Visual Project Management Fast Tracks Industrial Automation

Recently a Tier 1 automotive supplier came to us in desperation: They needed a duplicate pressure decay leak testing machine fast. As a returning industrial automation customer, they knew our typical project time was 16 weeks. But they wanted the machine in just eight weeks.

That eight-week timeline simply wasn’t feasible for us, still we wanted to help. We quoted 14 weeks for the project. The supplier accepted the quote, with fervent reminders that sooner would be better. We told them we would do everything in our power to expedite the order.

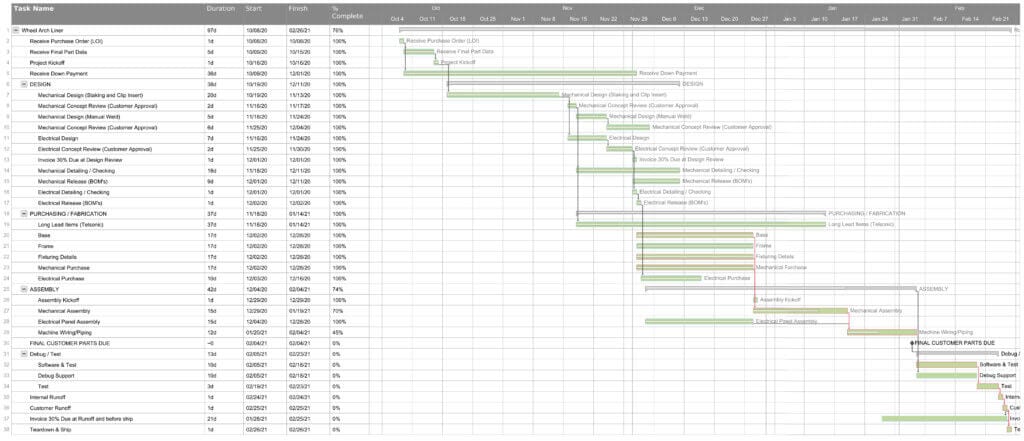

Fortunately, our visual project management system enabled us to jointly identify multiple opportunities in the build process to speed up production. Working together cooperatively, we proactively identified items that could increase production time if not caught early in the process. We were able to reduce our quoted lead time from 14 weeks to 12.

Project Management and Our 17-Step Process

At AMS, project management is a key pillar of our production process. The beauty of project management is that it can be used across multiple industries for projects of any size. For our industrial automation projects, which span the high-end medical, consumer, plastic processing and automotive markets, we use it from project kickoff through product delivery.

The Project Management Institute (PMI) has a well-established project management methodology that includes five distinct phases:

- Initiation

- Definition and planning

- Launch or execution

- Performance and control

- Project close

At AMS, we have integrated these steps into our 17-step production process. We begin using our project management system to drive each step of the process to ensure your new industrial automation equipment will function exactly the way you envisioned.

We have applied our decades of experience in working with customers to upgrade the standard project management process to provide a visually enhanced project management system. It allows us to keep you informed at each significant milestone. With a focus on work breakdown structure and Gantt charts, this incorporation of visual elements greatly enhances transparency and promotes collaboration.

Cloud-Based Project Management

We use a state-of-the-art, cloud-based project management system that gives us access to a complete suite of tools to effectively manage industrial automation projects. This cloud-based system allows us to leverage the latest available project-management technologies. With real-time data at our fingertips, we are always in the know regarding the precise status of your project.

As an AMS customer, you don’t need to learn our project management tool. We do all of the “heavy lifting” for the project management for each piece of equipment we build. Our weekly reports to you incorporate significant project milestones. Our goal is to make the production process worry-free for each and every client. The tool helps all of us by providing up-to-the-minute, real-time status updates.

Thursday Updates

Typically, our projects run about 16 weeks from project kickoff until shipment. Each Thursday, we email customers a progress report. This progress report includes a short written report along with photos or videos that provide a comprehensive snapshot of where we are in the project.

Our weekly email updates do not require any action on your part. We present you with the information simply for your peace of mind. Weekly phone calls or meetings are not required, but we are always available to answer questions or chat. Once you’ve passed the production baton to us, you can focus on the rest of your business needs.

In the final stages of the project, especially since the advent of Covid-19, we often use video to capture the acceptance test run. This footage assures you that the equipment performs to design specifications.

Organizational Transparency

Our visual project management system keeps everyone focused on a shared set of goals and timelines that enable us to complete your projects on time. Because any potential production impediments are discovered early in the process, we are able to work together to find time-saving resolutions. Our team members trust this process and openly share concerns to find solutions quickly.

I currently serve as the dedicated project manager for each of our industrial automation builds. Although I am the ongoing point of contact for your production process, standing alongside me are an entire team of experienced professionals including your sales representative, mechanical and electrical designers, assemblers, fabricators and prequalified vendors.

Together, we view our visual project management as a tool that supports our overall philosophy of making the industrial automation production process as seamless as possible. We take ownership of the production process, proactively resolve production issues and deliver machinery that you can count on working from day one.