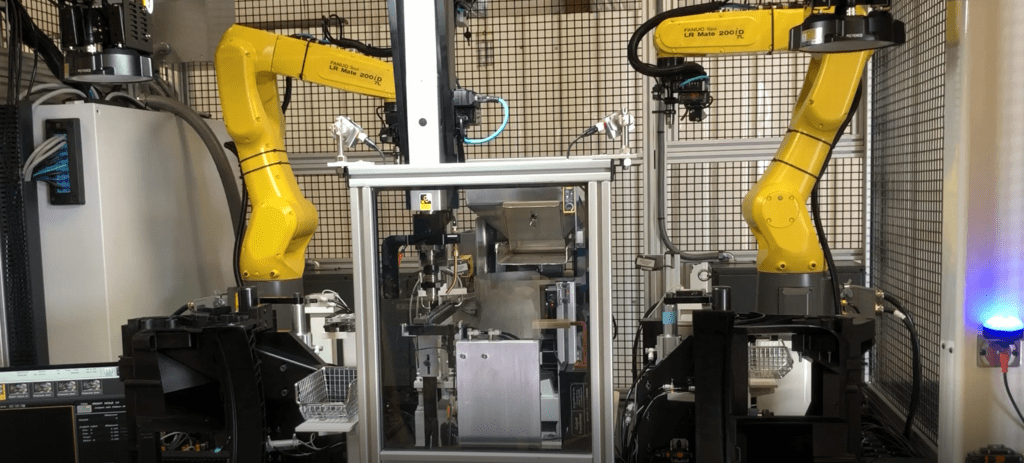

Assembly and Testing Systems for

Let AMS exceed your expectations with automated assembly and injection molding systems

Decades of experience

Engineering guidance

Deep knowledge of assembly and test systems

It’s Not Our First Rodeo

Experience with Plastic Parts Includes:

- Lawn and Garden Equipment

- Lawnmower Housings

- Household Appliances

- Lighting Equipment

Our Wall of Fame

At AMS, we pride ourselves on our previous projects and how we were able to help our customers solve their unique pain points. We can also look to past projects as potential solutions for our next challenge. This wall contains just a few of the many unique designs AMS has been able to complete. Explore the different industries, processes, and solutions we have provided.

Click a blue dot to learn more.

At AMS, we pride ourselves on our previous projects and how we were able to help our customers solve their unique pain points. We can also look to past projects as potential solutions for our next challenge. This wall contains just a few of the many unique designs AMS has been able to complete. View this page on a larger screen to explore the different industries, processes, and solutions we have provided.

Nut Insertion for Medical Industry

Leak Testing for Medical

AMS built a custom station using a Z-Axis air leak test instrument to ensure integrity of the part’s assembly and subassembly through a vacuum decay test.

Glue Dispensing and Curing for MedicalGlue Dispensing and Curing for Medical

Infrared Staking for Medical

Spot Welding for Medical

Ultrasonic staking Dial Table

Heated Nut Insertion for Plastic Processors

Collar Pressing and Ultrasonic Welding for Plastic Processor

Ultrasonic Welding for Automotive

AMS designed and built an ultrasonic welding machine to spot weld eleven locations per part. The machine has a non marking fixture and 2 stations back-to-back of one another that are able to operate independently of one another. One station for the RH side still and the other for the LH side still. The machine provides semi-automatic operation, poka-yoke functions, and completes the process in 37 seconds per side. Special components include a sonic weld nest and pneumatic powered lower drawer style loading fixture guided by THK rails.

Collar Pressing for AutomotiveCollar Pressing for Automotive

AMS designed and built a single-nested pneumatic collar press machine to assemble ten collars to a lower plate separator. This machine also featured a removable tooling plate and upper platen, allowing for rebuild to accommodate future programs.

Ultrasonic Welding for Plastic ProcessorsUltrasonic Welding for Plastic Processors

AMS built a machine using Branson Ultrasonic Welders and a shuttle system to weld a filter material into the bottom of automotive carbon canisters. The machine was equipped with three full wavelength ultrasonic horns.

Wheel Liner for AutomotiveWheel Liner for Automotive

AMS designed and built an RH/LH clip driving machine for a German Tier 1 supplier of interior plastic underbody components. The machine featured magnetic clip retention and sensor verification for correct installation and orientation of the metal clips to the wheel liner.

Press Machine for AutomotivePress Machine for Automotive

AMS Designed and built an ultrasonic staking machine to weld two plastic components together on a class A surface interior dashboard component. The machine featured two 35kHz ultrasonic welding actuators mounted to a single platen for precise weld consistency and clean cosmetic surfaces.

Leak Testing and Precision Fastening for AutomotiveLeak Testing and Precision Fastening for Automotive

AMS was involved in the subassembly process for a pipe comp with a heat shield for one of our automotive manufacturers. We built machines to join the heat shield with screwdriving and leak test the assembled part through a line of integrated AMS systems.

Leak Testing and Precision Fastening for AutomotiveLeak Testing and Precision Fastening for Automotive

AMS was involved in the subassembly process for a pipe comp with a heat shield for one of our automotive manufacturers. We built machines to join the heat shield with a screwdriver and leak-test the assembled part through a line of integrated AMS systems.

Leak Testing, Precision Fastening, and Nut Insertion for AutomotiveLeak Testing, Precision Fastening, and Nut Insertion for Automotive

AMS designed and built a single nest, AMS NI-401 platform style induction heated nut insertion machine to install two brass M4 nuts into an air cleaner housing. This machine uses a SCARA Robot for the nut insertion, a vibratory bowl feeder, and induction heating system for the inserts. The machine jigs contain pneumatic and electric quick connections for interchangeability.

Trust AMS to take your most ambitious plastic processing projects from start to finish

Wish You Could Do More?

Are you sacrificing productivity and profitability with inferior machine systems? Is your company as fast and strong as it could be? Do you worry about mitigating risk and making deadlines that are getting closer every day? When you don’t know what you don’t know, you need a seasoned partner.

Plastic Processing manufacturers look to AMS for:

- Guidance through design, build and integration

- Transparent project management and clear communication

- Deep knowledge of assembly and test systems

There’s So Much Riding on Your Decisions

We understand you need solid design, fast and accurate automation and support. After all, it’s your company’s reputation and your next promotion on the line. You’re feeling the squeeze from internal and external stakeholders. When everyone is counting on you, who can you count on?

With AMS on your side, you get:

- 99.5% on-time delivery record and 97% customer satisfaction

- Top engineering and design brain power

- The right automation machines for your application

- 24/7 hotline support that never sleeps

Your Next Idea Deserves a Champion

AMS has served the plastic processors industry for more than 20 years, offering standard and customized products, including injection molding systems, that exceed expectations and add maximum value. The AMS difference is in our proven 17-step process, which ensures quality and customer satisfaction.

AMS offers solutions for a number of plastic assembly applications and the expertise to help you choose the best system. We offer several types of plastic joining systems to automate welding with various methods and materials, including injection molding systems. AMS can also evaluate your business’s assembly operation and recommend ways to improve quality and productivity through the use of innovative automation.

We can help you identify, design and implement a solution that fits your operations. Most of all, we offer comprehensive project management that keeps you up to date continuously. No more wondering if your automated machine systems will show up on time. No more fears about surprise cost overruns. We want customers to read us like an open book.

Surefire Automation Plan

- Share your automation goals with one of our application engineers.

- Share your vision and goals.

- Grow your business with custom automation systems.