Reliable plastic assembly

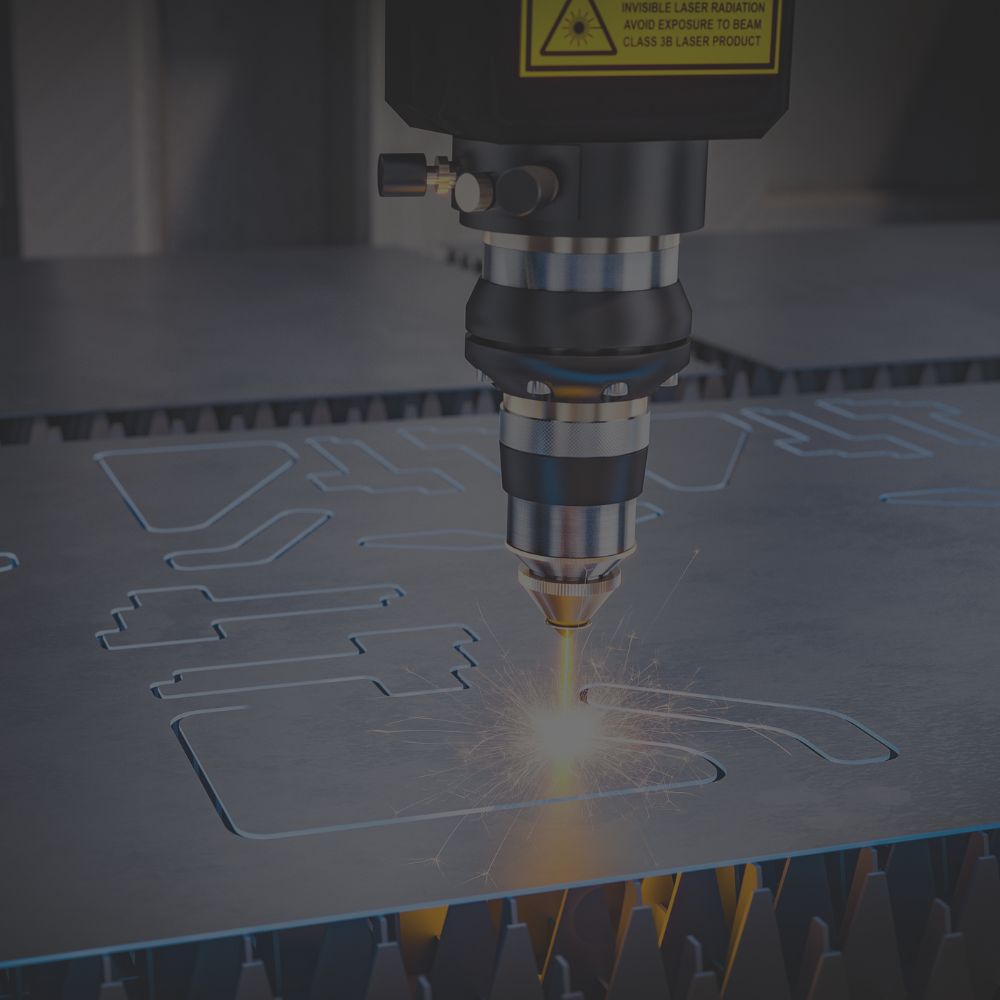

Range of welding methods

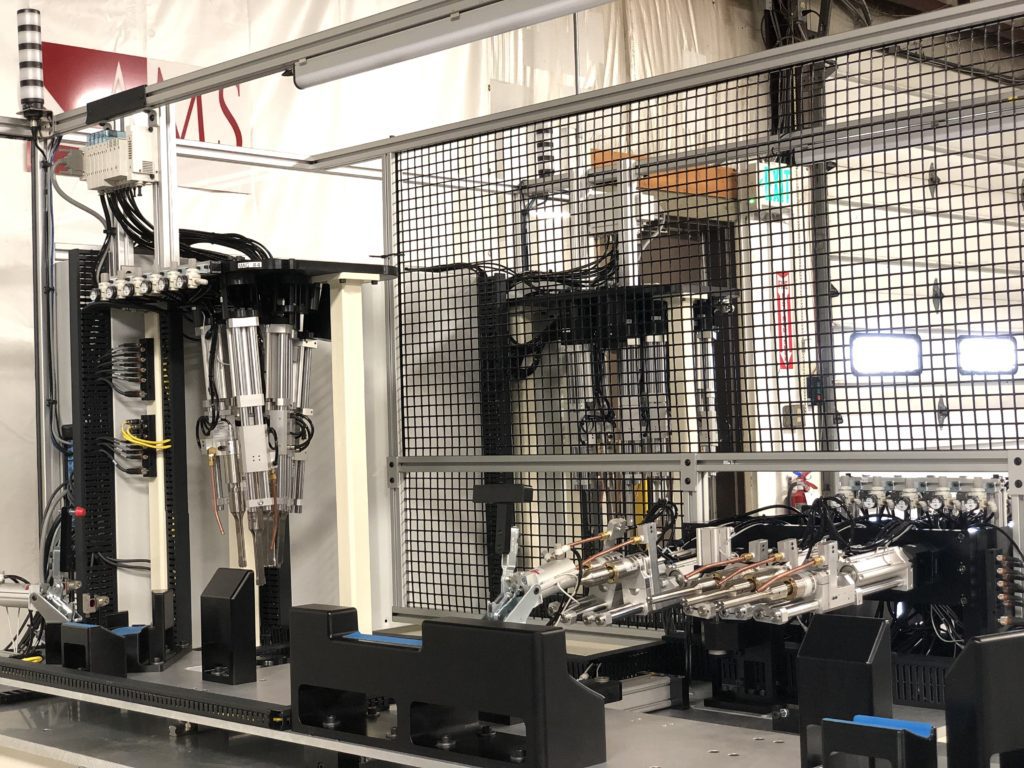

Automation that powers productivity

Discover All the Advantages of Automated Ultrasonic Plastic Welding

Are Outdated Operations Stunting Your Growth?

Going without the right plastic assembly systems can cost you time and money. You risk falling behind competitors that are consistently making quality parts for less. Choosing the wrong automation systems provider could endanger the success of your product launch.

Plastic Assembly Systems from AMS

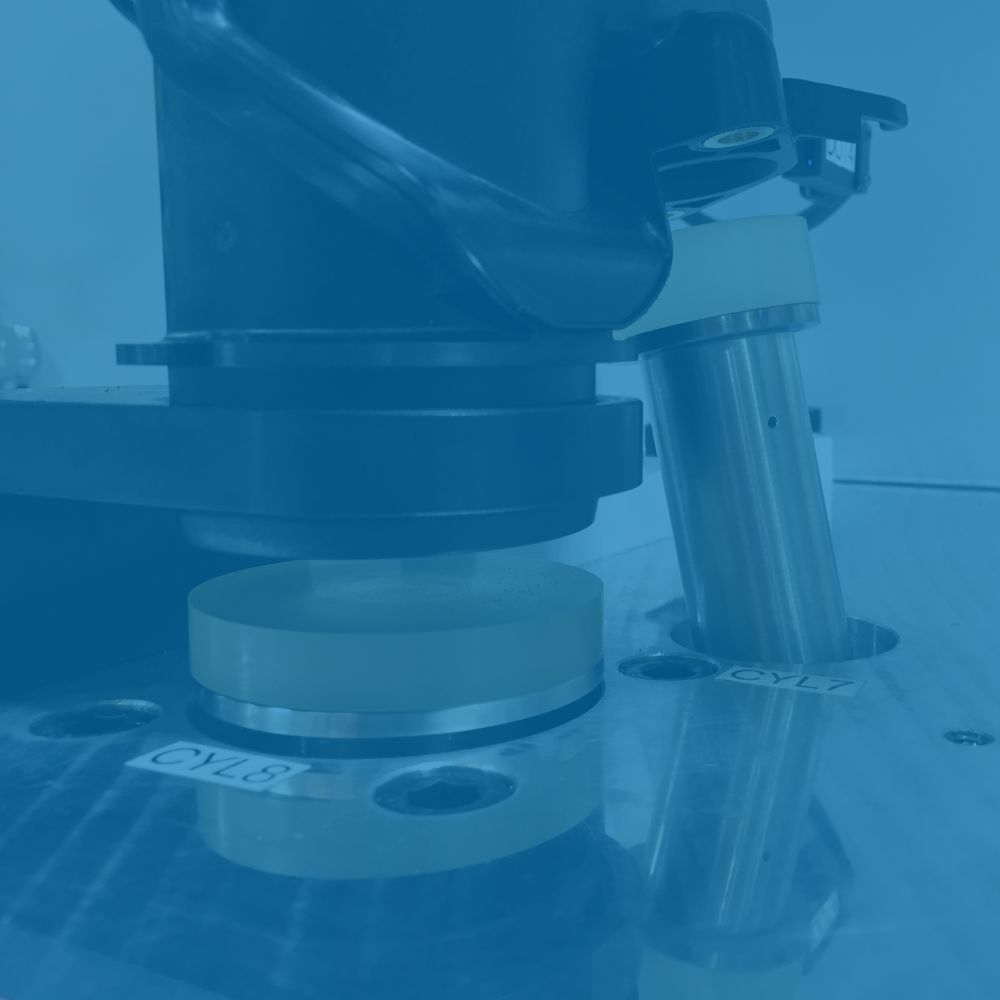

Thermal plastic staking

Ultrasonic plastic staking

Increase Productivity and Efficiency with Plastic Assembly Operations

To get ahead, you need to increase throughput, minimize handling and improve quality. Automating your plastics assembly gives you the competitive edge. And while we offer standard ultrasonic welding machines, spot welding, staking, textile welding and more, our engineers are experts at customizing systems to our customers’ exact application needs.

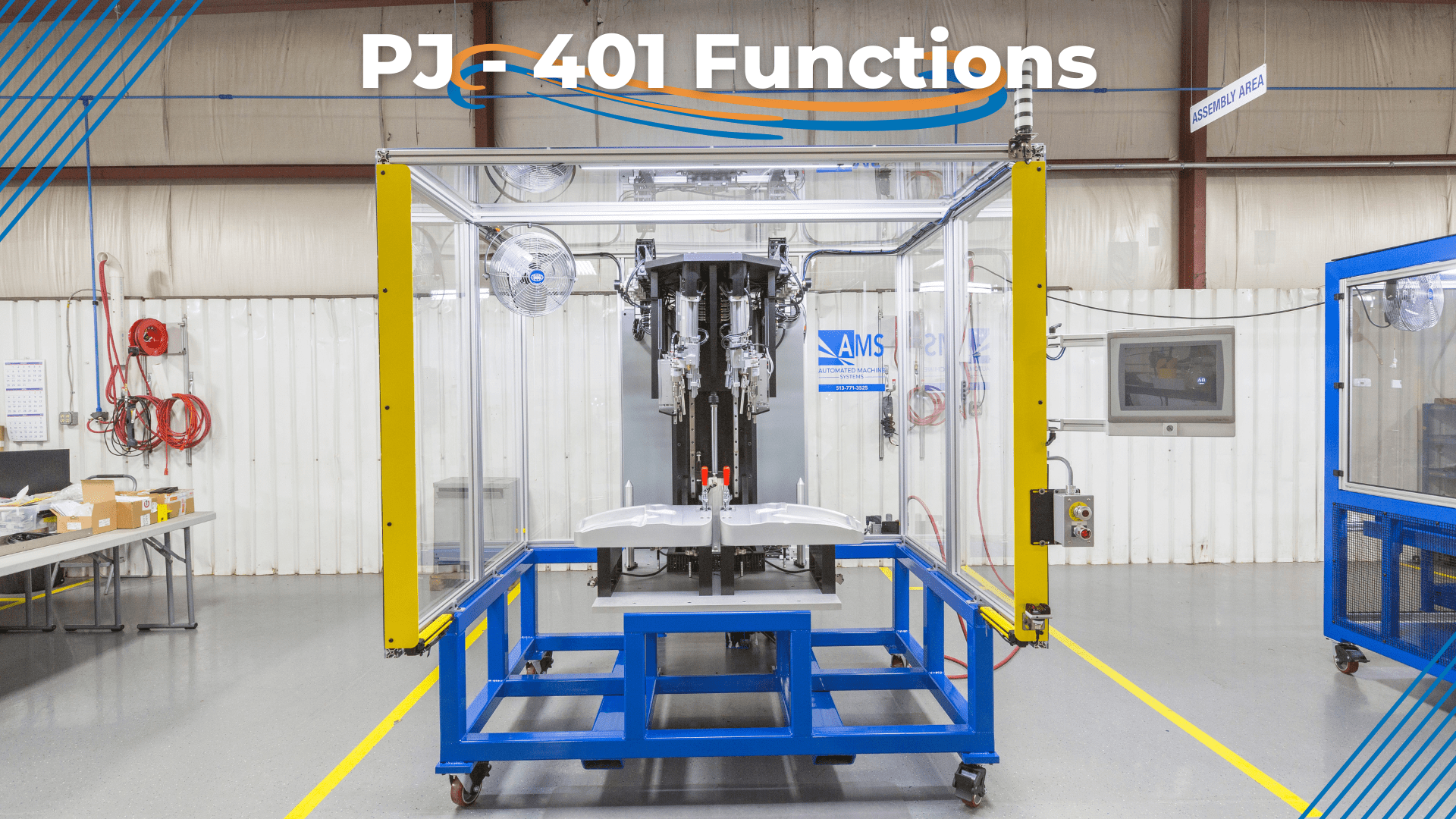

Front Light Curtains

Sturdy tubular steel frame base

Extruded Aluminum FrameExtruded Aluminum Frame

Ultrasonic Welding Actuators

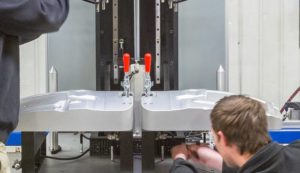

CNC Milled Contoured part nest

Indicator Stack Light

Human Machine Interface

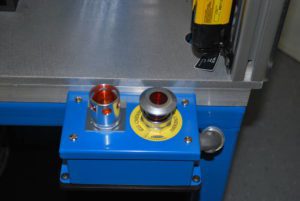

Emergency Stop and Reset Button

Cycle Start Touch Sensor

Precision Plastic Welding With The PJ-401

AMS designed the Plastic Joining PJ-401 for ultrasonic plastic welding applications requiring precise welding temperatures and pressures, exact locations, high levels of error-proofing, and repeatability to ensure consistent welding.

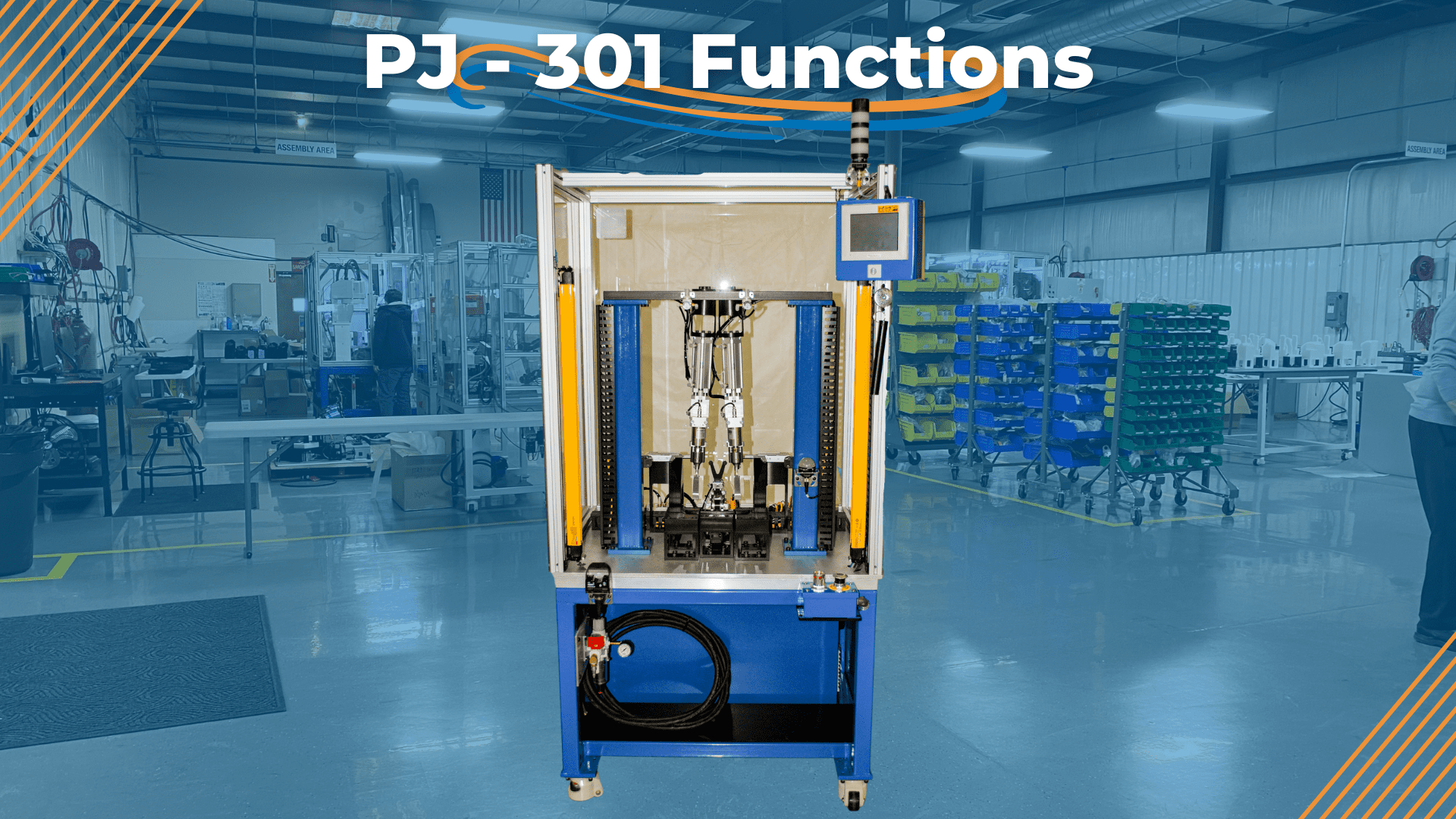

Ultrasonic Plastic Welding With The PJ-301

The AMS Plastic Joining PJ-301 is a versatile, semi-standard platform for ultrasonic staking, forming and spot welding. With semi-automatic operation, poka-yoke functions and outstanding productivity, the PJ-301 is a great general purpose plastic joining machine.

PJ-301 is easily configurable and reconfigurable for future requirements. Start designing yours today with out downloadable data sheet.

Ultrasonic Welding Actuators

Translating Upper Platen

CNC Milled Contoured Part NestCNC Milled Contoured Part Nest

Extruded Aluminum Frame

Human Machine Interface

Human Machine Interface

Light Curtains

Emergency Stop and Reset Button

Emergency Stop and Reset Button