Medical industry experience

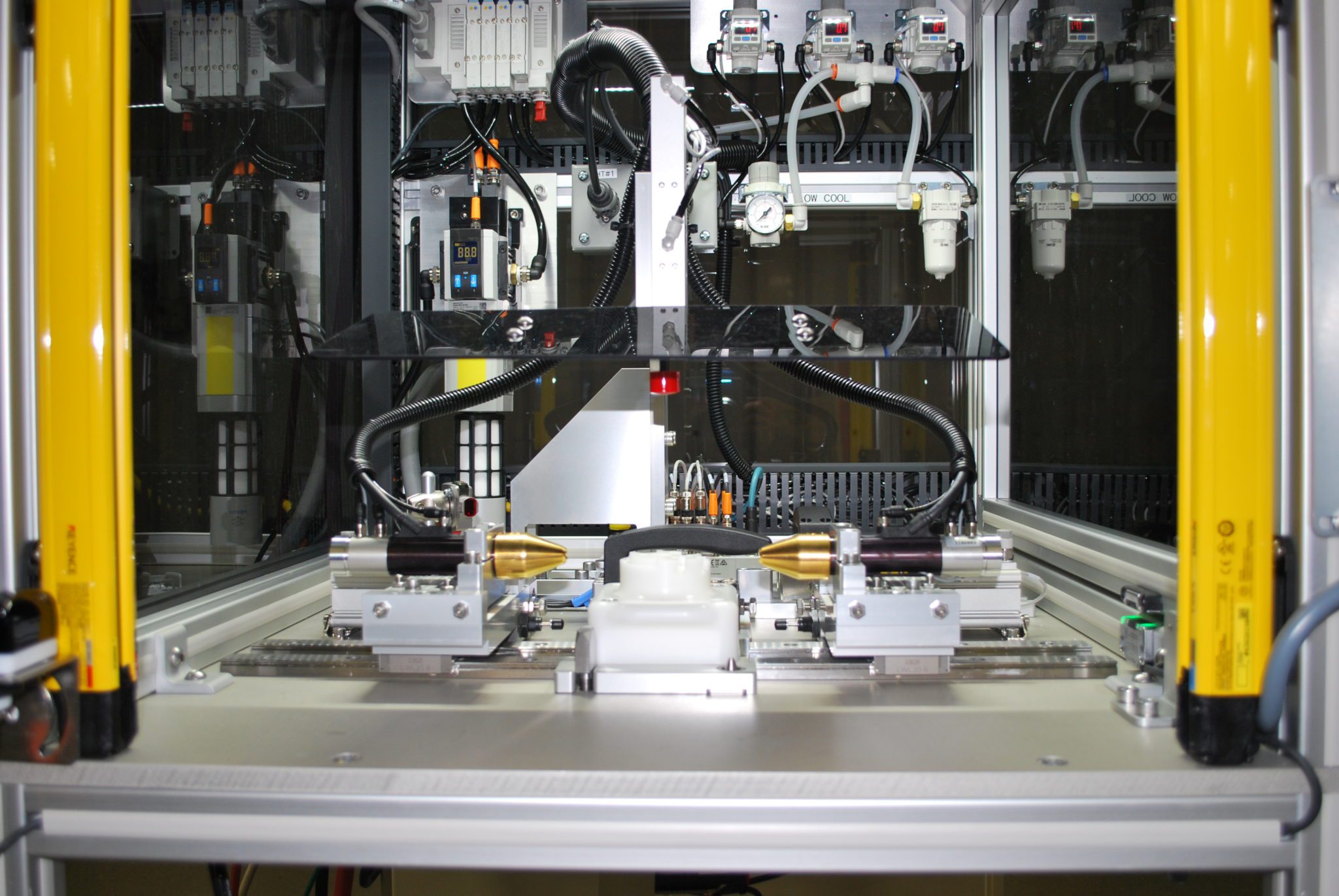

Reliable systems

Understanding of FDA Regulations

View & Download our AMS MedFlex Cell Data Sheet

What Are the Benefits of Automation in the Healthcare Industry?

Still not sure if automation is the right cure for your manufacturing headaches? Watch or read our case study about a Cincinnati-based medical device manufacturer that used automation to fast track their medical device assembly.

Our Automated Medical Manufacturing White Paper Will Help You Envision New Ways of Operating

Reading this white paper will help you: