Discover the Benefits of a Ultrasonic Plastic Welding Solution

Download the PJ-401 data sheet today.

For applications requiring precise welding temperatures and pressures applied, exact locations defined, high levels of error-proofing, and repeatability to ensure consistent welding, the PJ-401 is an ideal choice. This model is often used to produce large and small automotive accessories such as wheel liners and hood assemblies. Other applications include medical devices and plastic processors needing stress-free joints and cosmetic surfaces.

Ready to join forces? Start your ultrasonic welding automation journey with AMS today: Use the PJ-401 data sheet to start designing your ultrasonic plastic welding machine. With our semi-standard designs and proven 17-step process, we deliver the right solution, on time and to your specifications.

This data sheet will help you:

- Learn how the PJ-401 functions.

- Determine if it is the right solution for your application.

- Evaluate mechanical and electrical requirements.

- Review ordering options.

Use this free data sheet to take your next (or first) step toward reduced cycle time with a semi-automatic ultrasonic welding system.

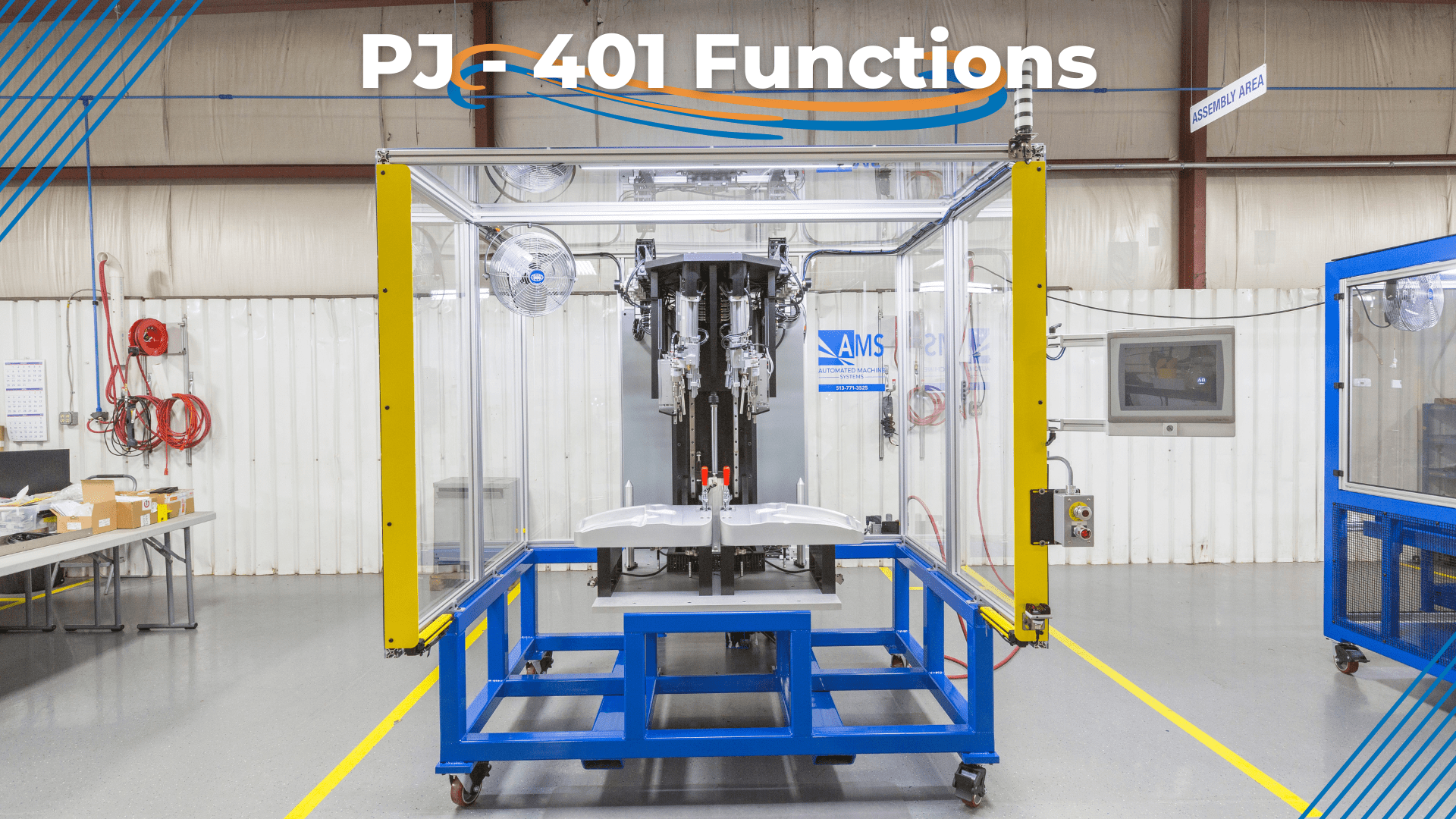

Front Light Curtains

Sturdy tubular steel frame base

Extruded Aluminum FrameExtruded Aluminum Frame

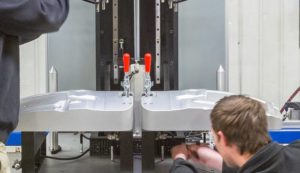

Ultrasonic Welding Actuators

CNC Milled Contoured part nest

Indicator Stack Light

Human Machine Interface

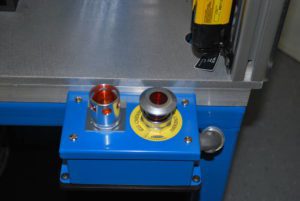

Emergency Stop and Reset Button

Cycle Start Touch Sensor

Stuck in the Ultrasonic Welding Weeds?

Going without the right ultrasonic plastic welding machine can cost your business time and money. Choosing the wrong automation systems provider can also cost your business. You risk falling behind competitors that have the ability to make quality parts for less.

Ultrasonic plastic welding uses high-frequency mechanical vibrations transmitted through thermoplastic parts to create frictional heat at a joint interface. The frictional heat generated causes the part interfaces to melt and fuse while pressure is applied. This technique is fast, efficient, non-contaminating and requires no consumables.

We know you want to nail down the right welding systems to successfully launch your products. Our ultrasonic plastic welding machines and automation systems are delivered on time and function flawlessly. Our systems are backed by customer support to help every worker in your plant, no matter the shift.

AMS will help you obtain repeatable ultrasonically welded results. We will assist you in analyzing the welding characteristics of thermoplastics and bring our understanding of how polymer structure and other factors affect the weldability of different polymers. Our engineering team will ensure that you consistently get the results you expect. Download the data sheet above for more information, then schedule an application review with our pros.