PLASTIC ASSEMBLY

Our machines meet your toughest requirements for plastic assembly.

LEAK TESTING

Ensuring leak-free components and devices through advanced leak testing system.

Nut Insertion

We meet your needs with designs refined by two decades of experience.

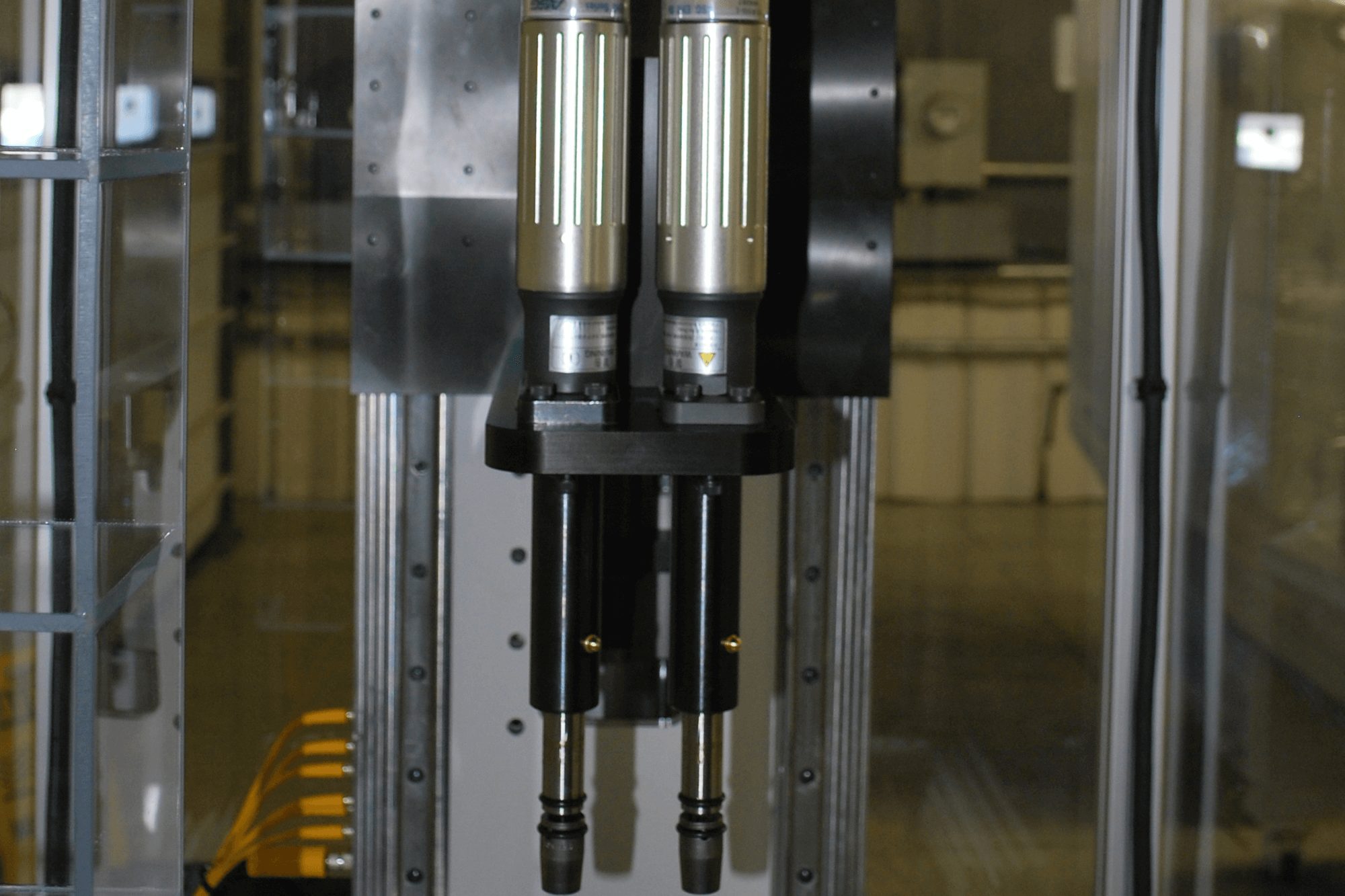

Precision Fastening

Boost output with consistent, traceable and precise results.

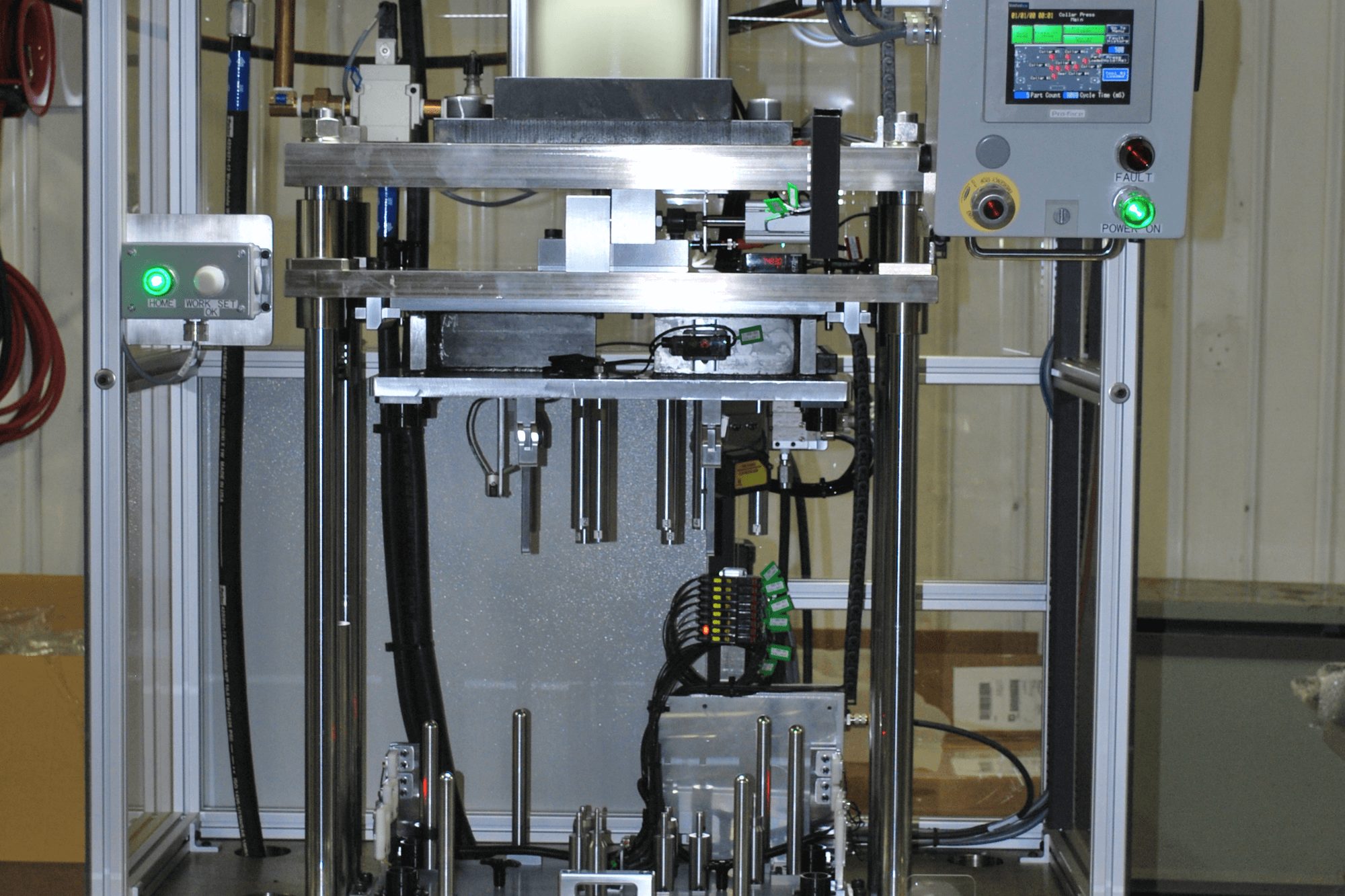

Press Machines

Precisely control depth and force with systems designed for your pressing requirements.

Glue Dispensing

Increase efficiency in manufacturing with accurate and repeatable automated adhesive application.

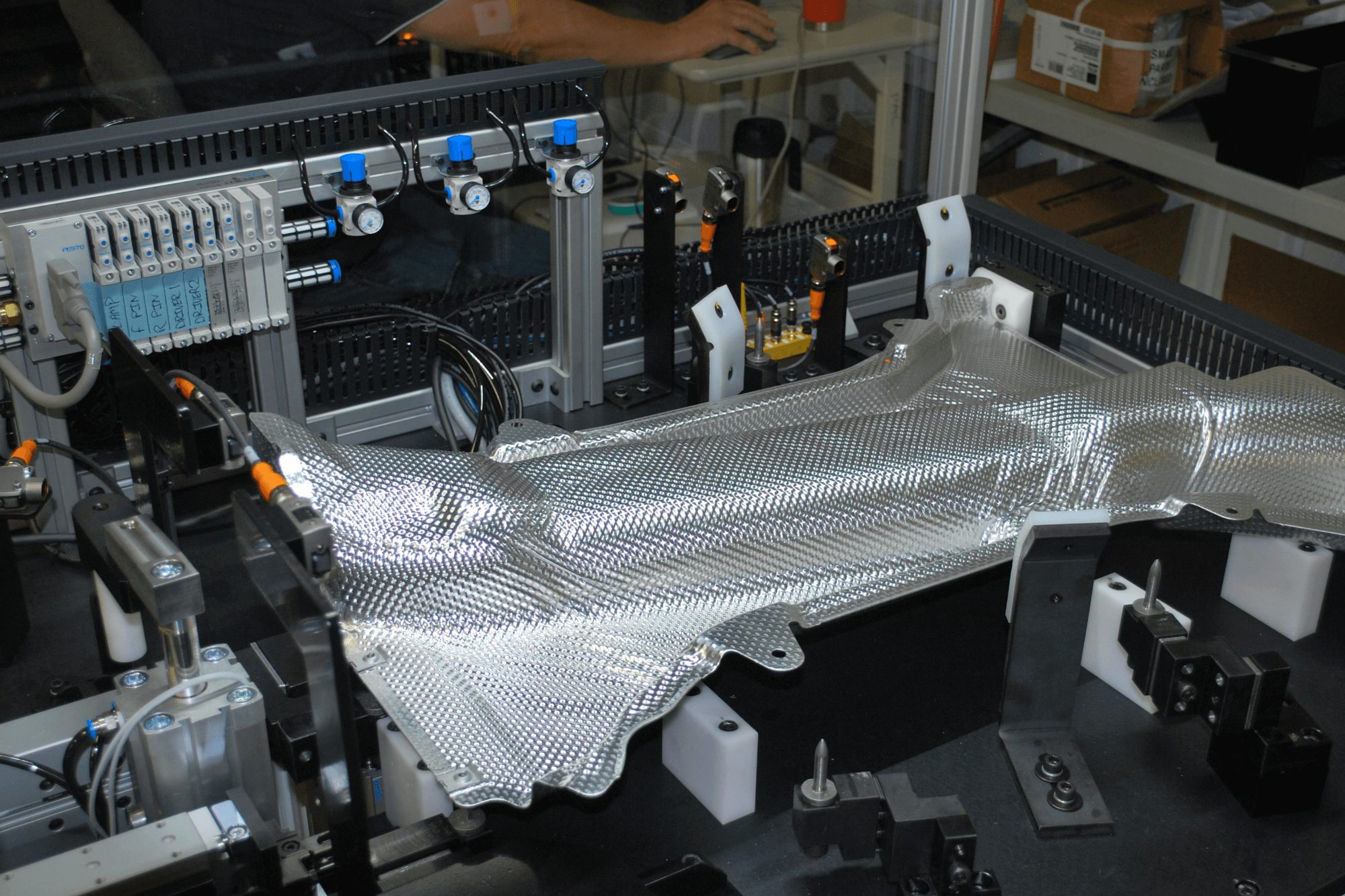

Clip Installation

Using an innovative head and press platen design, our automated equipment powers your productivity. We design clip installation machines for maximum efficiency.

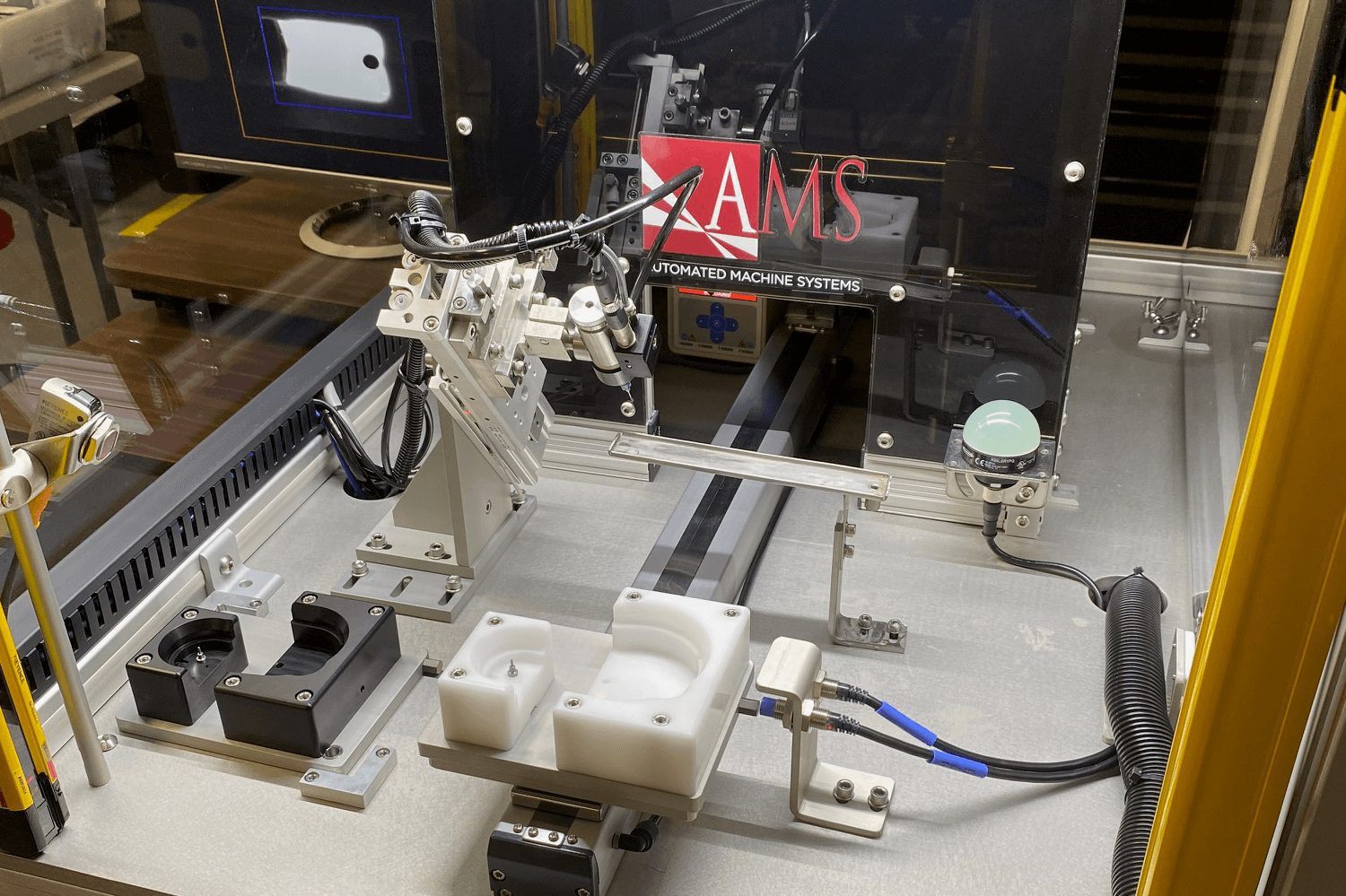

ROBOTIC SYSTEMS

Take your assemblies to the next level with improved accuracy, speed and repeatability around the clock.

Automation Technologies & Solutions

Sonic welding offers a fast, efficient, and reliable method for joining thermoplastics, making it a valuable tool in industrial manufacturing alongside techniques like adhesive bonding and bolting. While each method has its strengths, sonic welding excels in applications requiring fast cycle times, clean welds, and strong bonds for non-critical structural components.

Ultrasonic welding uses high-frequency vibrations to create clean, permanent bonds between compatible thermoplastics. This technology offers speed and precision, making it ideal for high-volume production of non-critical parts where fast cycle times and strong, yet localized, welds are essential.

Laser welding offers a high-precision and clean joining solution for various materials, including metals and some plastics. This automation technology uses a concentrated laser beam to melt and fuse components, creating strong, narrow welds with minimal heat distortion. Due to its precision and control, laser welding are ideal for applications that require intricate welds, join dissimilar materials or have thin parts.

Heat staking is a cost-effective method for joining plastic components in manufacturing. It uses localized heat to melt a designated area on one plastic component, allowing it to be pressed against another part and form a secure bond upon cooling. This method is ideal for high-volume production, particularly for attaching fasteners, clips or creating leak-proof seals in non-critical areas.

Spin welding is a versatile method for joining plastics with precision and strength. Spin welding is fast and clean, using friction heat generated by spinning one part against a stationary one. This creates a strong weld that is ideal for high-volume production of simple, leak-proof parts.

Robotic integrators are the bridge between robots and production lines. They allow these machines to seamlessly integrate with existing systems, boosting efficiency and revolutionizing the production process.

Hot welding uses heat to melt and fuse plastic parts together. It's a popular choice for factories because it's fast and makes sturdy bonds for many plastic products. However, hot welding can sometimes warp the plastic and only works with certain types.