In-depth leak testing automation expertise

Customized for a range of industries

Automation that powers productivity

The Measure of Your Success

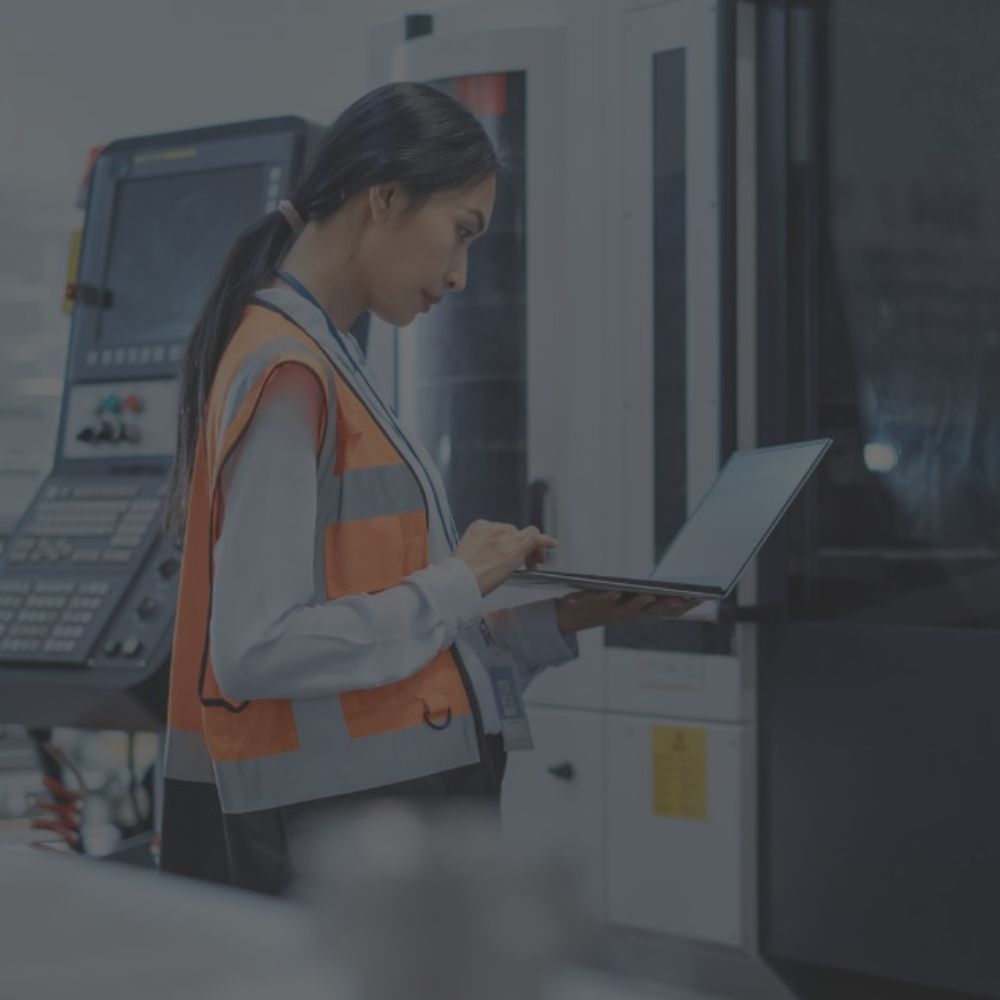

Are You Risking Customer Loyalty and Profits?

Failing to meet stringent requirements could damage your customer relationships and your company's reputation. Choosing the wrong automation systems provider could endanger your product launch.

Reliable Leak Testing from AMS

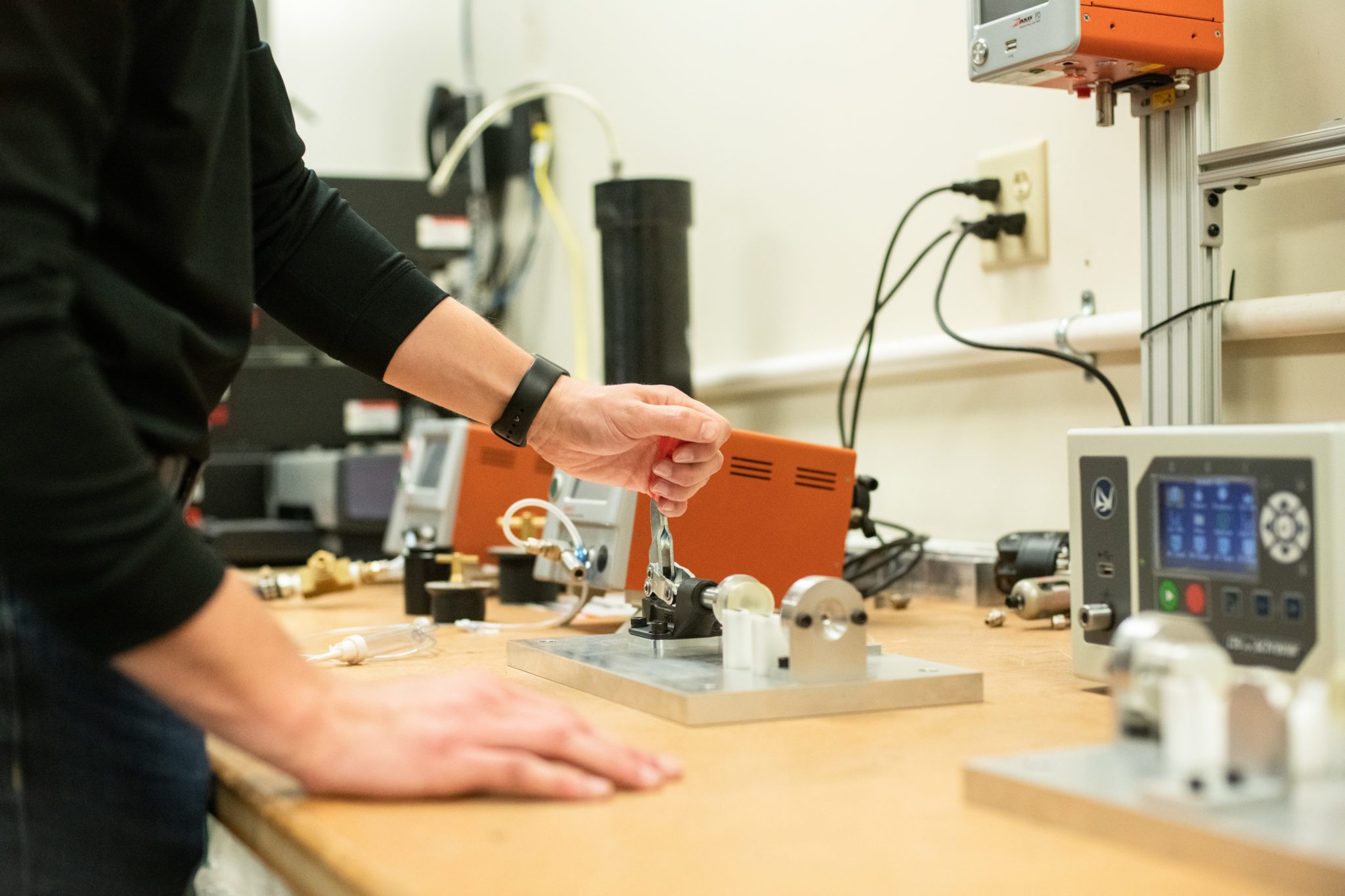

Fixtures to position and secure the part

Sensors to ensure the part is positioned properly

Automatic sealing of all openings

“Poka-yoke” quality control testing to ensure all components are assembled correctly and functioning properly

Reliable Leak Testing from AMS

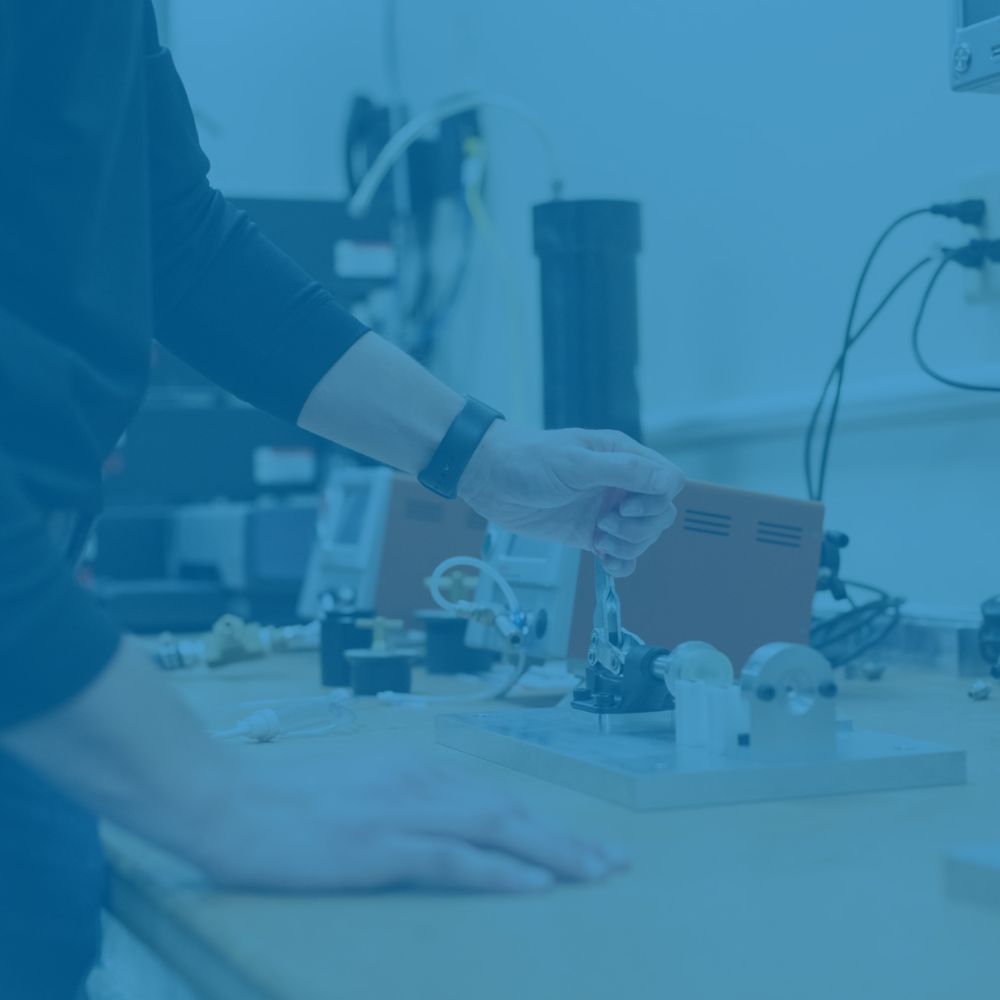

THE LT-201

AMS’s two models of leak test systems use a semi-standard platform for leak testing. The LT-201 offers manual functionality with good cycle times and meets customer needs for lower cost, improved quality and minimum floor space.

Front Light Curtains

Front Light Curtains

To ensure safe run over time, the front light curtains will stop the machining process if it detects the operator.

Sturdy tubular steel frame base

Sturdy tubular steel frame base

Extruded Aluminum FrameExtruded Aluminum Frame

Frame with Lexan panels and LED Lighting to ensure safe cycles.

Removable Tooling Plate

Removable Tooling Plate

Two 110V Convenience OutletsTwo 110V Convenience Outlets

Human Machine Interface

Human Machine Interface

For operator messaging, machine set up, and advanced controls.

Emergency Stop and Reset Button

Emergency Stop and Reset Button

Lets the operator control the machine and stop if necessary.

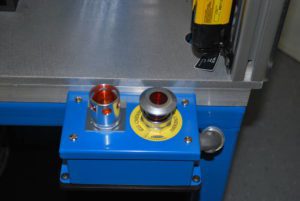

Cycle Start Touch Sensor

Cycle Start Touch Sensor

Responds to a finger blocking light rather than to pressure to ensure a safe start every time.

THE LT-401

For higher volumes, the LT-401 features semi-automatic operation, outstanding productivity and easy reconfiguration for future requirements.