Get Informed With the MedFlex Cell Data Sheet

It’s free. Download now.

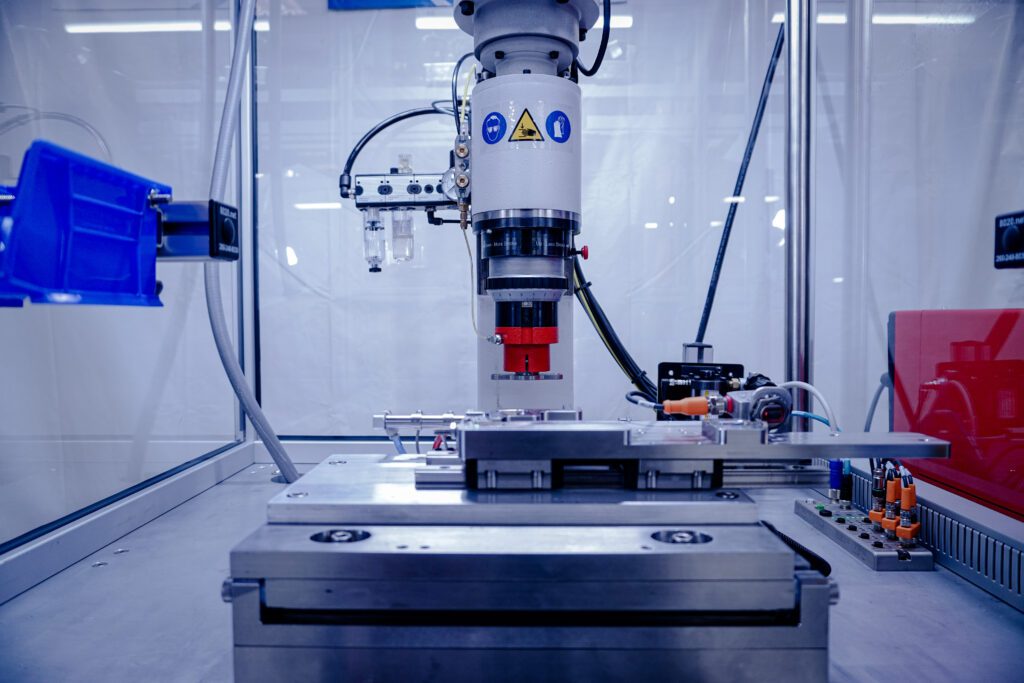

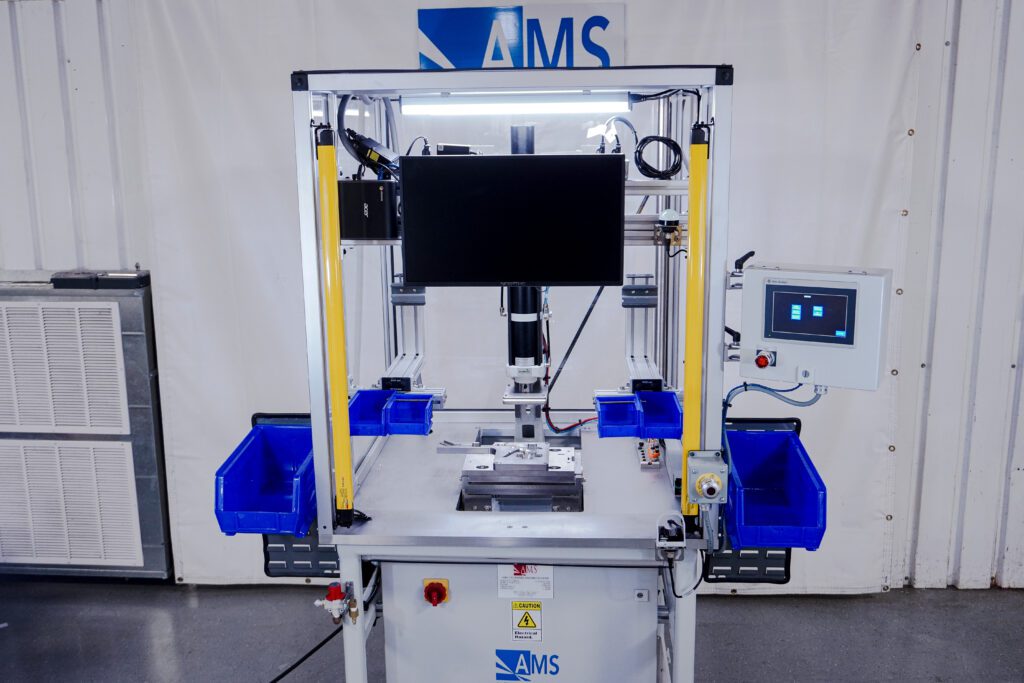

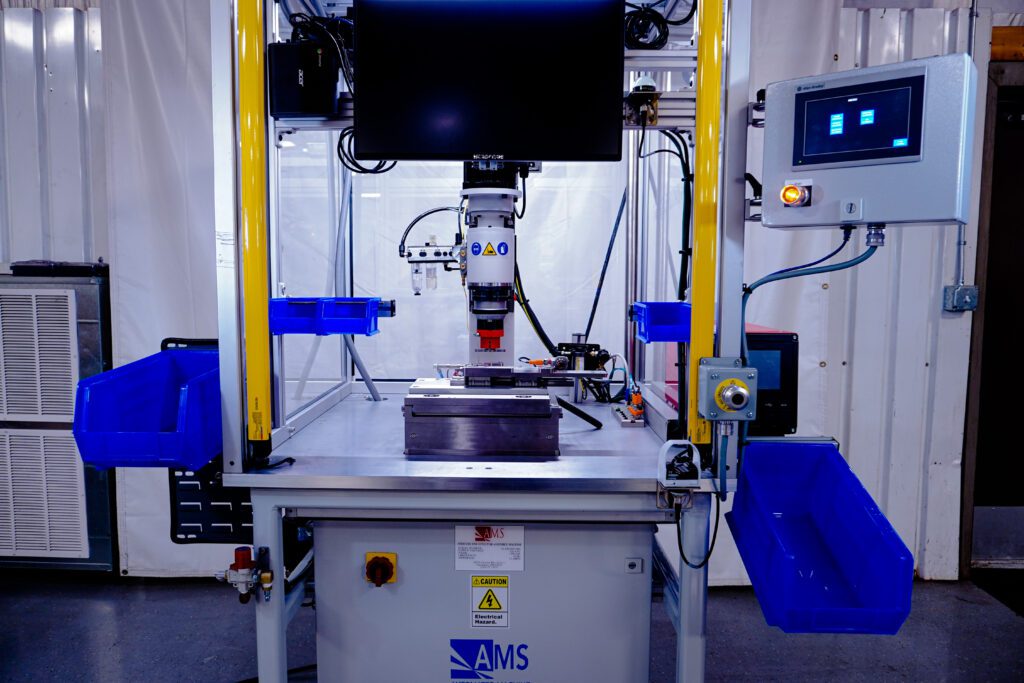

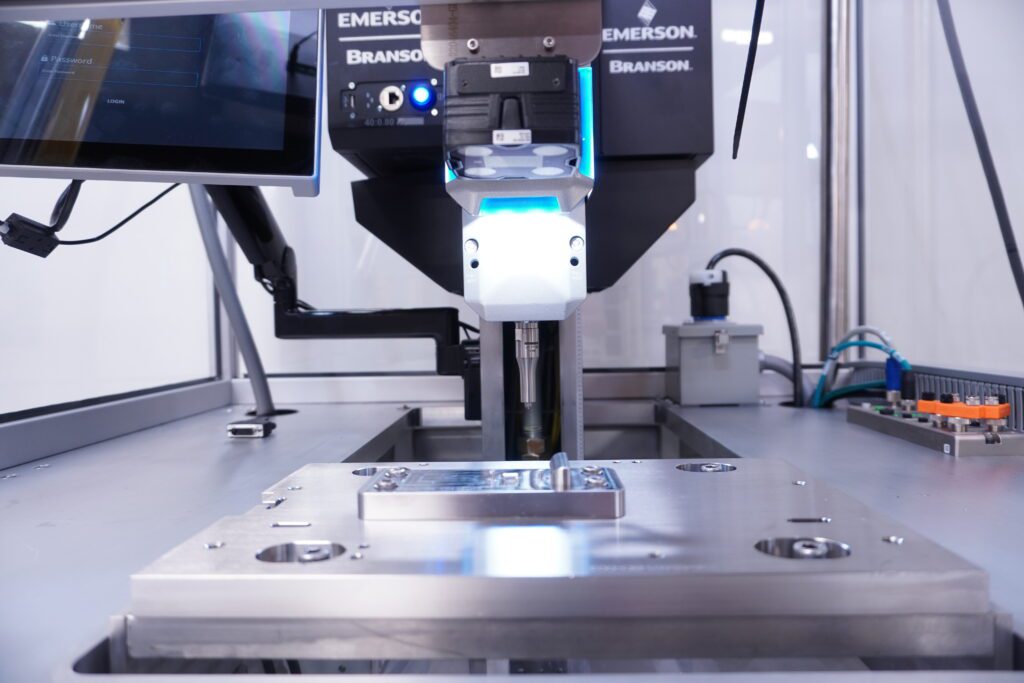

This medical kit assembly provides a semi-standard platform for precision medical assembly, installation and testing. The MedFlex Cell was designed to be configurable for a variety of healthcare device assemblies. From assembling catheter manufacturing equipment to leak testing medical hoses, this versatile cell will increase your manufacturing and assembly productivity by automating several steps.

What Are the Benefits of Automation in the Healthcare Industry?

Still not sure if automation is the right cure for your manufacturing headaches? Watch or read our case study about a Cincinnati-based medical device manufacturer that used automation to fast track their medical device assembly.

Medical Industry Automation Articles

Manufacturing Industrial Products with Automatic Glue Applicator Machines

Imagine for a moment that you’re an industrial manufacturer considering your options for joining components together. Welding, bolting, riveting and friction fitting all come to mind, but none ideally suits the project you’re working on. In particular, the solution you’re after needs to offer lower per-unit costs, moderate structural strength and minimal complexity or weight…

Eight Tips for Automated Medical Device Product Assembly

Using automation in the assembly of medical devices offers many advantages for a company. The implementation of automated systems into medical device manufacturing allows companies to enhance the quality of their products. Moreover, they can also offer a safer alternative to manual labor, and contribute to an increased production efficiency. Here is a list of…

Tips for Medical Device Automation Success

There are so many advantages when it comes to medical device automation. It not only is a cost-effective option, but also improves consistency, reduces waste, increases efficiency and much more. That being said, automating your medical device manufacturing systems can be a complicated process that requires proper planning and implementation in order to be successful. …

IP Ratings for Medical Leak Testing Standards

Have you ever heard of IP ratings for medical leak testing? The IP rating system, also known as ingress protection rating system, is a set of standards that determine how well an enclosure can stand up against conditions on the outside such as dust and moisture. These standards are used in medical leak testing. The…

Glue Dispenser Machine Applications

Here’s a fun fact: It’s almost certain that the device you’re reading this article on was assembled using some degree of adhesive bonding. Nearly all handheld and personal electronics utilize an applied glue, sealant, pot fill or coating, as do countless other manufactured goods found in every industry. No wonder glue dispenser machines are in…

Automate Your Catheter Manufacturing Equipment

With new and improving technology, many companies have recently been implementing automated medical device manufacturing equipment into the workplace. When you automate catheter manufacturing equipment, you can increase productivity and efficiency as well as reliability. Having automated equipment in manufacturing production can also improve the quality and price effectiveness of your product. Speed Up the…