Precision controlled heat and position

Consistent accuracy

Integrated quality controls

Getting the Most from Heated Nut Insertion

Hot nut insertion is the process of inserting a threaded nut into a plastic part. There are three main technologies for related applications: inductive heating, conductive heating and ultrasonic insertion. Pairing six-axis robots and integrated quality controls with this technology allows for accurate, repeated insertion of heated nuts into parts of all configurations.

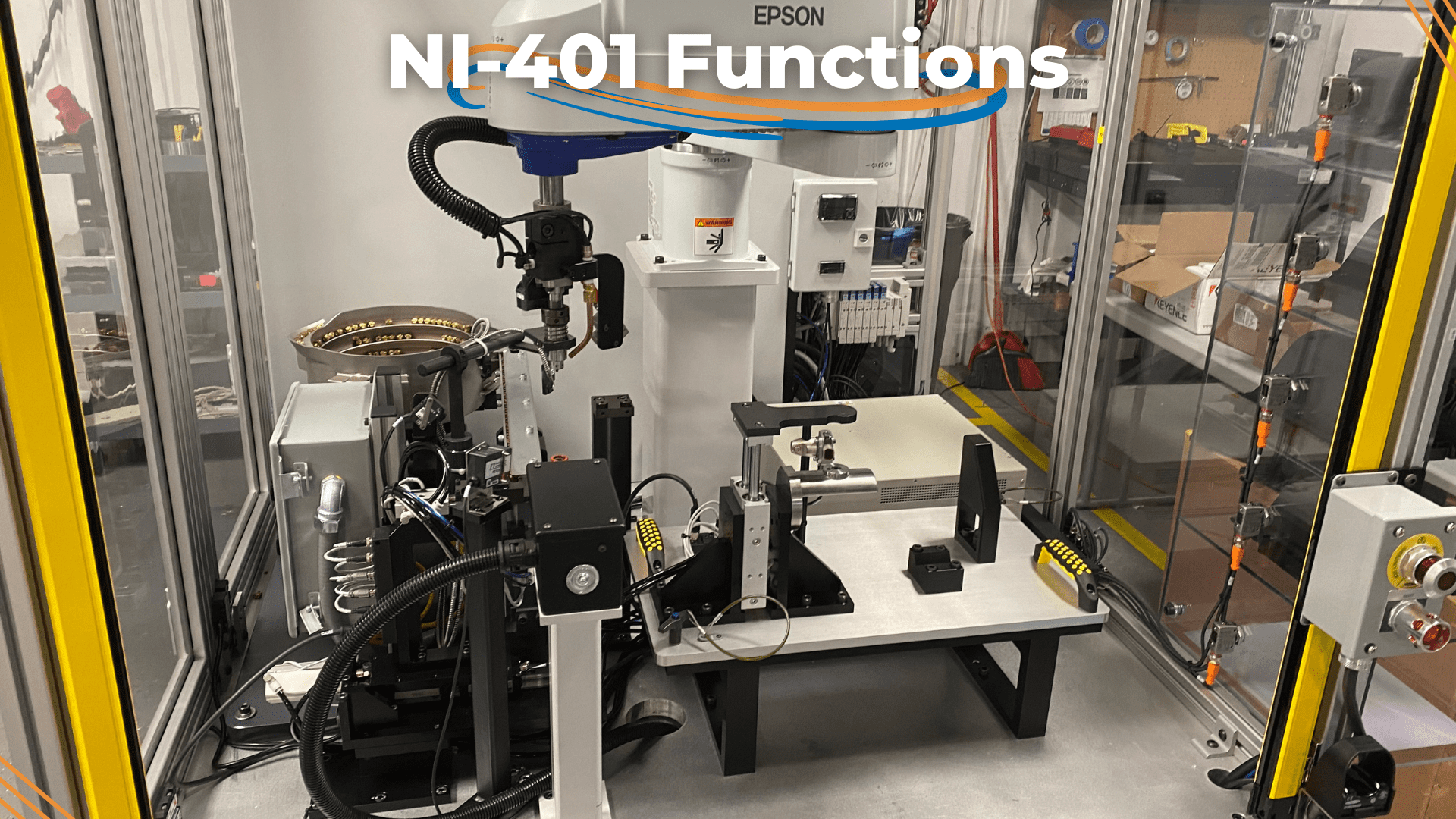

Vibratory Bowl

Inductive Heating Coil

Nut Insertion HeadNut Insertion Head

SCARA Robot

Custom Fixture with Sensors

Light Curtains

Emergency Stop and Reset Button

Cycle Start Touch Sensor

We are the Nut Insertion Experts

Our nut insert platforms are some of our most popular standard products. There are three primary functions that the machine performs to create great parts consistently: Nut singulation, Heating, and Transport/insertion. Our NI platform allows us to be able to commit to a ±0.2mm tolerance on the nut insertion. We can commit to this standard because of the high accuracy and repeatability of the Epson robot and our AMS nut insertion head that is able to create consistent insertions across part variability due to the dynamic, adjustable positioning sleeve.

Inductive hot nut insertion

Inductive hot nut insertion involves heating the nut in a magnetic field produced by an inductive coil.

Conductive Heating

Conductive heating is the process of either pre-heating the plastic prior to insertion, or partially inserting the nut and heating both the plastic and the nut directly via a heated probe.

Ultrasonic insertion

Ultrasonic insertion uses a sonotrode that contacts the insert directly to generate heat through friction.