Deep application knowledge in our core competencies

Unmatched speed of response: 24/7 hotline

Weekly visual project communications

Don’t Risk Your Job to a Jack of All Trades

Our deep application knowledge means your project will be fast tracked for success

Request an In-Person Tour

PLASTIC ASSEMBLY

Tap into our extensive experience in all types of ultrasonic welding processes like seam, spot, staking and textile.

LEAK TESTING

Trust us to design and build your pressure decay, vacuum decay, mass flow air, and helium and hydrogen gas leak test systems.

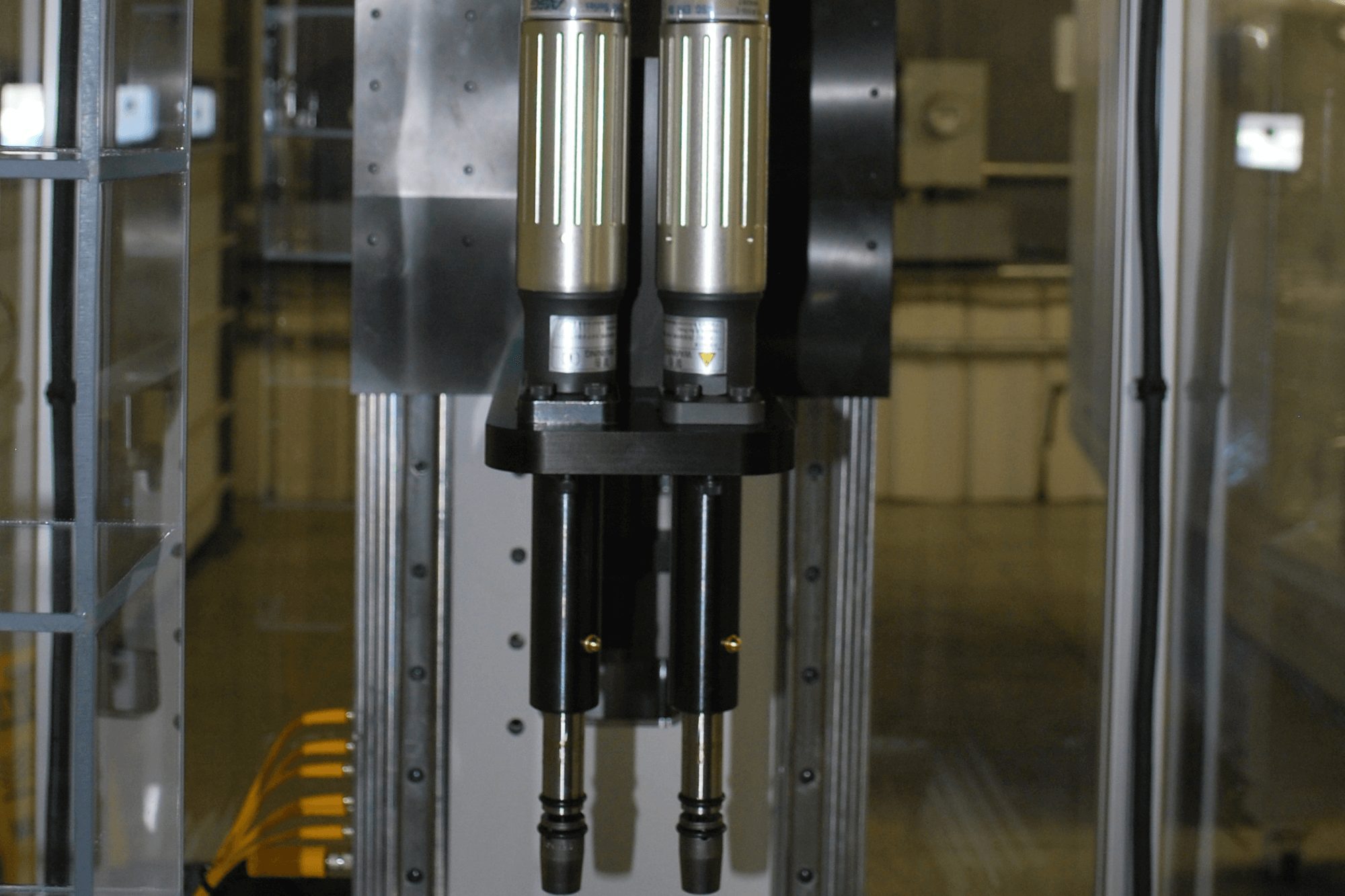

NUT INSERTION

Rely on our decades of experience in building heated nut insertion machines that use electromagnetic induction to insert threaded nuts in a variety of sizes and plastic types.

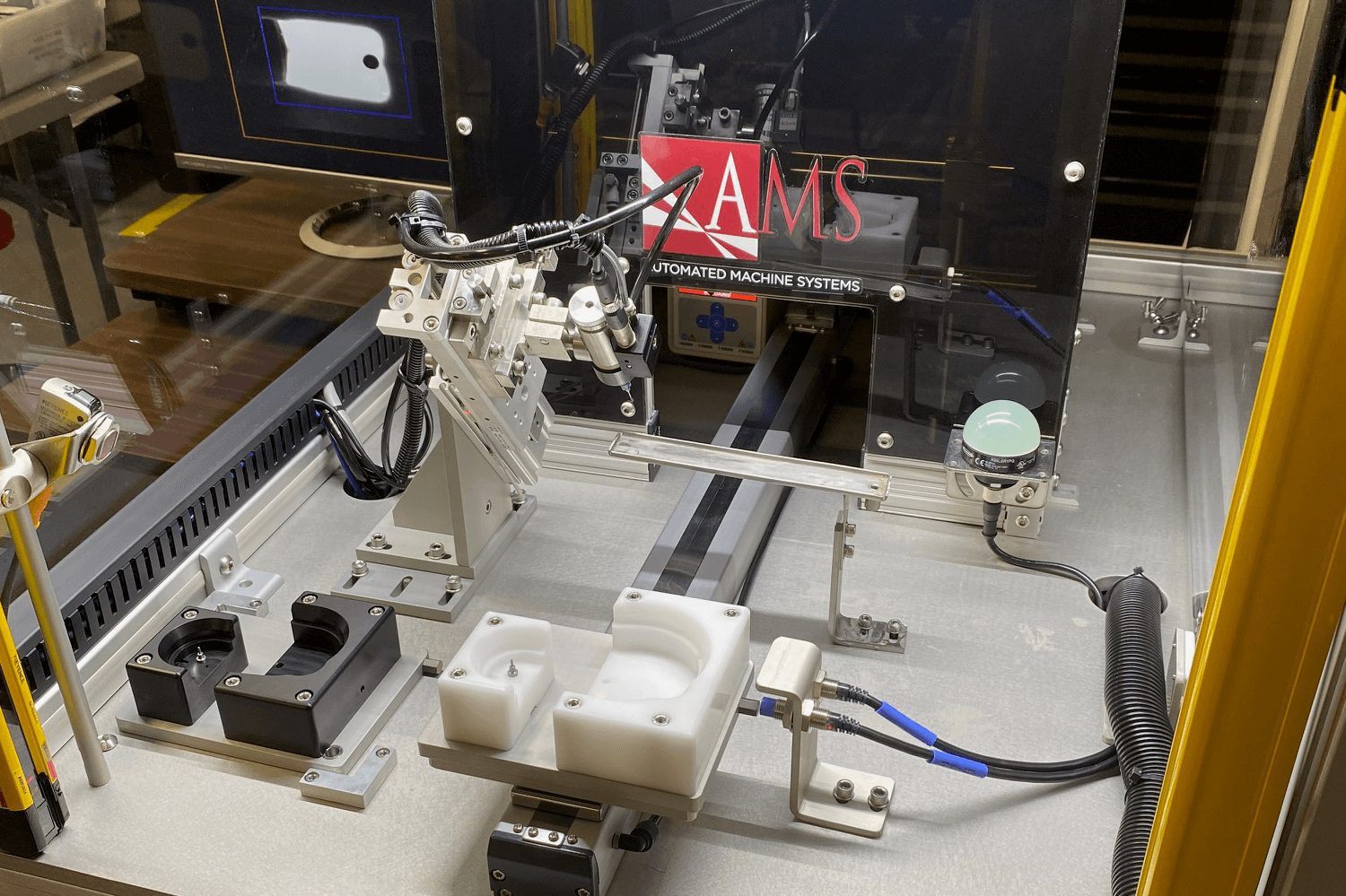

PRECISION FASTENING

Hold it together with our complete line of precision fastening products that meet the tightest tolerances and levels of error-proofing.

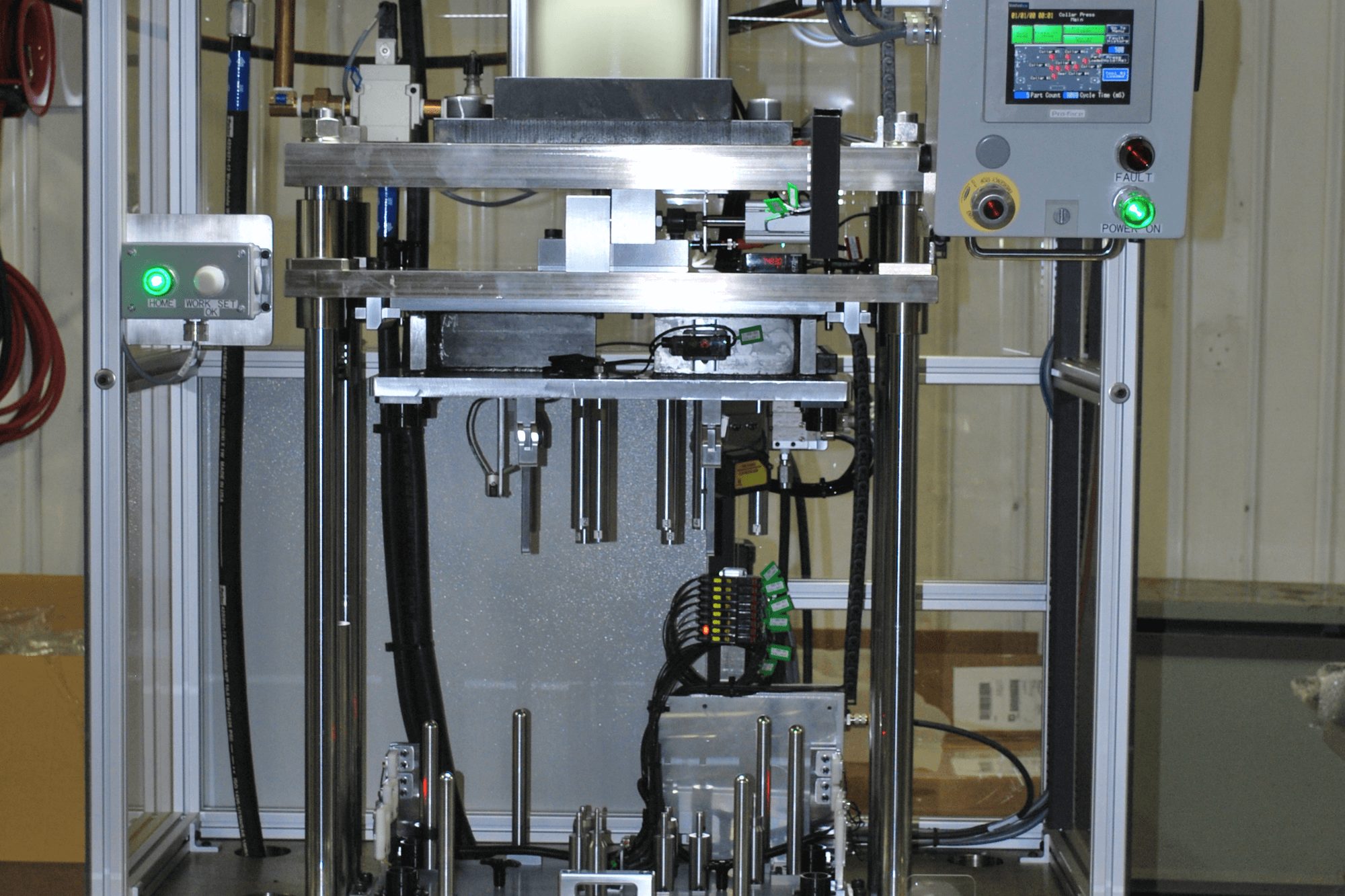

PRESS MACHINES

When you need to insert compression limiters, our custom press machines make the process fast and flawless.

GLUE DISPENSING

Making today’s adhesives work for your application requires precision gluing and curing systems.

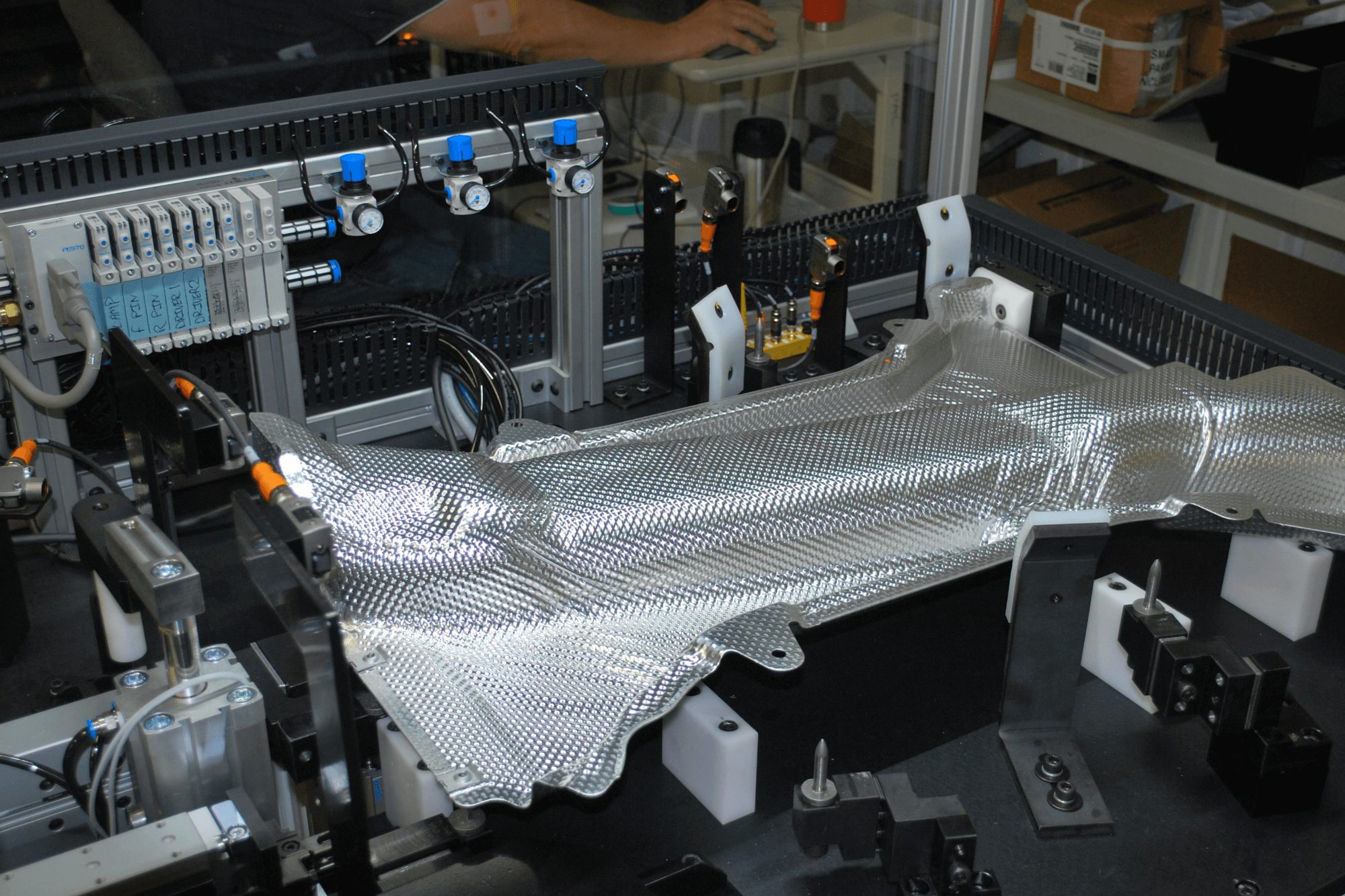

CLIP INSTALLATION

Our equipment makes quick work of installing metal and plastic clips onto automotive components.

ROBOTIC SYSTEMS

Manufacture around the clock by incorporating Robotics into your assemblies, while at the same time improving accuracy, speed and repeatability

Automation Technologies & Solutions

Sonic welding offers a fast, efficient, and reliable method for joining thermoplastics, making it a valuable tool in industrial manufacturing alongside techniques like adhesive bonding and bolting. While each method has its strengths, sonic welding excels in applications requiring fast cycle times, clean welds, and strong bonds for non-critical structural components.

Ultrasonic welding uses high-frequency vibrations to create clean, permanent bonds between compatible thermoplastics. This technology offers speed and precision, making it ideal for high-volume production of non-critical parts where fast cycle times and strong, yet localized, welds are essential.

Laser welding offers a high-precision and clean joining solution for various materials, including metals and some plastics. This automation technology uses a concentrated laser beam to melt and fuse components, creating strong, narrow welds with minimal heat distortion. Due to its precision and control, laser welding are ideal for applications that require intricate welds, join dissimilar materials or have thin parts.

Heat staking is a cost-effective method for joining plastic components in manufacturing. It uses localized heat to melt a designated area on one plastic component, allowing it to be pressed against another part and form a secure bond upon cooling. This method is ideal for high-volume production, particularly for attaching fasteners, clips or creating leak-proof seals in non-critical areas.

Spin welding is a versatile method for joining plastics with precision and strength. Spin welding is fast and clean, using friction heat generated by spinning one part against a stationary one. This creates a strong weld that is ideal for high-volume production of simple, leak-proof parts.

Robotic integrators are the bridge between robots and production lines. They allow these machines to seamlessly integrate with existing systems, boosting efficiency and revolutionizing the production process.

Hot welding uses heat to melt and fuse plastic parts together. It's a popular choice for factories because it's fast and makes sturdy bonds for many plastic products. However, hot welding can sometimes warp the plastic and only works with certain types.

CHOOSE THE RIGHT AUTOMATION PARTNER

Get the Checklist

This simple one-page checklist can help you gather the information you'll need to talk with potential automation partners, including:

Rely on Our Experience in Your Industry

Count on our engineering team, application development lab and decades of experience

2021, 2022, & 2023 Cincinnati Best Places To Work

AMS is honored to be named a 2021, 2022, and 2023 Best Places To Work in Cincinnati! We extend our congratulations to all the great businesses celebrating this award. We credit our success to the adoption of the Great Game of Business (GGOB) process.

Testimonials

Zach F., Manufacturing engineering manager, medical device manufacturer

“AMS exceeded expectations in all areas: communication, responsiveness and execution. We plan to leverage their resources again in the future.”

Eric B., Senior manufacturing engineer, automotive

“AMS is awesome to work with and very responsive. They listen to the issues we have and resolve them.”

Dan G., Engineering manager, automotive supplier

“Professional, knowledgeable and customer-focused, AMS is 100 percent involved in projects from the prototype stage through completion of the project at our facility.”