Automation 101: Advanced Technology for Heat Staking

Lighter materials, faster assembly times, lower costs, higher quality: These are the major goals of industrial manufacturers today, and frame up the primary lines along which these manufacturers compete. In many ways, all of these goals point toward plastic materials and plastic fabrication as resoundingly beneficial for modern manufacturing. One plastic joining technology in particular, heat staking, has seen an explosion of new applications and techniques in recent years. This growth stems from advances in compatible materials, bond chemistry and staking methods. Let’s take a closer look at these advanced technologies, their fabrication methods and the automated systems that make them possible.

Heat Staking in Industrial Manufacturing

A great way to start the discussion around heat staking is to grasp what it entails. Imagine having two pieces of plastic sheeting that you wish to fasten together. Traditionally, the only way to mechanically bond these two pieces would be to drill holes through both, line the holes up, insert a mechanical fastener such as a bolt or a rivet through the holes, and tighten down the fastener. The fastener here provides an external clamping force to hold the pieces together.

With heat staking, the general concept is the same – using a fastener of sorts to clamp one material against the other – but without the need for separate mechanical hardware. Picturing the two separate plastic sheets again, envision that the lower sheet has a small cylinder (or “stake”) molded into its surface and sticking out a small amount. The second sheet will have a hole through it as in the first example, this time formed when the sheet was originally molded and not drilled after the fact. The two sheets are assembled together with the lower sheet’s stake protruding through the hole in the second sheet. A tool is used to heat up the stake until it partially deforms and collapses down onto the upper sheet, securing it in place. This process is known as heat staking.

The benefits of this process (also known as thermal plastic staking) are numerous, making this fastening technology widely applicable in industrial manufacturing in these markets:

- Automotive

- Electronics

- Medical device

- Aerospace

- Consumer goods

- And others

Here are the primary benefits of heat staking, along with a few challenges facing these applications.

| Benefits | Challenges |

| Only one of the joined pieces needs to be plastic; can be used for securing dissimilar components to plastic bases easily | Temperature control is critical in ensuring a successful stake, and must be accurately monitored |

| Can be performed very quickly, well suited for high-volume, low-cost applications | Large assemblies can be difficult to stake in one operation without sophisticated machinery, especially when the part is highly irregular in shape |

| Uses minimal physical force, protecting delicate or small assemblies | Staking at lower-than-required temperatures can lead to stress damage to plastic components |

| Applied heat is precisely focused on the stake, making it safe to use near sensitive components | Some off-gassing, fumes or plastic particulate can be expected when heating plastics |

| Works with heavy-duty, glass-reinforced plastics for high-strength bonds |

For small- to medium-size assemblies with relatively flat profiles, heat staking is often the least expensive, most repeatable joining method available. The bonding time of heat staking can be slightly longer than other methods, due to the need for heating, holding and then cooling the stake (explained in more detail below). Still, this extended time factor is often an acceptable trade-off for simplicity and low deployment costs. Further, heat staking allows for a wide selection of stake head size, shape and density, making it more applicable to custom parts.

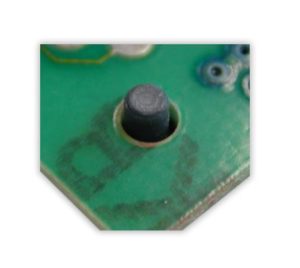

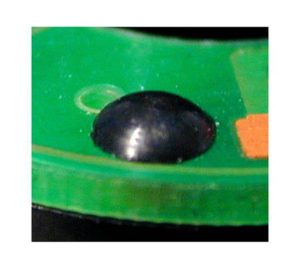

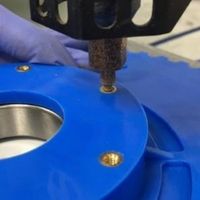

Below are photos showing a raw stake ready to be formed, followed by a completed stake with a dome cap formed to retain a silicon circuit board.

Heat Staking Methodology

In more detail, the steps for heat staking are as follows:

- An assembly of two separate pieces is placed into a heat stake machine, with the parts positioned and aligned.

- A heated element is lowered onto the stake, making light contact and is held for a set amount of time while the plastic material heats to its glass transition point (where it just begins to melt but stops short of becoming a flowing liquid).

- The heating element is physically pressed down onto the stake, deforming the stake into a cap or bead over the upper material. When both materials are thermoplastics, the stake can fully mold into and bond with the upper material.

- With pressure still applied, the heating element is disengaged and a cooling source is applied (such as compressed air). Once the part is sufficiently cooled, the bond is complete and the heating element is lifted out of place.

Explaining the steps for completing a heat stake is useful for our next discussion topic: how manufacturers employ heat staking technology in advanced fastening applications. The function of deforming a stake over a piece of material, fastening both together, is only the beginning of heat staking possibilities. Anywhere that we can deform a piece of plastic in a way that facilitates a bond with another material or component, through the application of heat and pressure, is a good candidate for a heat staking process. Manufacturers continue to creatively apply heat staking along these lines. Several of the most common solutions in wide scale use today are described below.

It’s worth noting that not only can the applications of heat staking be creatively configured, but so can the energy sources used in the process as well. Staking plastics can be heated with electrical current or hot air, and cooled with compressed air or separate cold plates.

| Heat Staking Studs This is the simplest form of heat staking, following the steps outlined above in bonding two materials together by deforming a stake protruding from the base material over an upper material. Many cap and head sizes, styles, and profiles can be used. source |

| Heat Staking Inserts This process presses a metallic, female threaded insert into a plastic base material, providing a threaded connection fitting for use in attaching separate components with a mechanical fastener. The process of staking the threaded insert is identical to stud staking: Heat the base plastic, apply force to set the insert, hold until deformation is complete, then cool. source |

| Membrane Staking (Porous Membranes)Found most commonly in medical devices, bonding a membrane material into a plastic base is a more recent development in heat staking technology. As long as the membrane media and the base plastic are compatible, heat staking offers a very effective bonding solution that is also inherently hygienic (due to the use of inert plastics). source |

| Membrane Staking (Impervious Membranes)A variant of the above membrane staking concept, this version provides a continuous bond for thin, impervious membranes against base plastic materials, both securing and sealing the two components together. Keypad membranes in medical or sanitary devices are good examples. source |

| Light-Duty Plastic Welding Heat staking can serve as a mild plastic welding solution, as well. For separate components of similar material that need to be fused together, heat staking technology can easily heat, bond and cool these materials in place of more expensive processes. The image to the left shows a retention ring bonded to a flat tab by heat staking. source |

| Large Staking In the image to the left, a pair of large plastic fluid nozzles are heat staked into metallic threaded adaptors at their bases. Large staking applications such as these are possible by very precise heat application, finely controlled plastic deformation, and modulated cooling to deter cracking. source |

From the above examples, we can see that heat staking can serve so many more applications than just forming a stake cap in small assemblies. With the direction that heat staking technology is developing, we might soon need to change our definition of heat staking to a form of “heated bonding,” where heat and pressure applied to a plastic part can create a mechanical bond between dissimilar, separate components in nearly any shape, size or orientation.

How to Automate Advanced Heat Staking

Traditional heat staking is very straightforward to perform, whether by hand or by an automated machine. Hand heat staking is ideal for one-off, purely custom, very low-volume fabrication projects where repeatability or inline quality control are not factors. The manual version tends to be found in proof-of-concept test labs and small custom manufacturing shops, but assemblies of a higher scale call for some degree of heat staking automation (if for no other reason than operator safety, freeing personnel from handling hot tools near fume-producing materials).

Most manufacturers looking to produce a volume of parts involving a heat staking process will begin with a small, semi-automatic machine. These systems require manual placement, alignment and orientation of the materials to be staked, while the system only controls the heating, forming force and cooling steps using automatic components. A small logic controller will store time, force and temperature recipes for each staking process, as these parameters will vary by material and stake design. The heating element will move via an actuator, or alternatively, the part fixture may raise up to the heating element and lower once complete. Operators remove the completed part, inspect and repeat for the next part.

Once part volumes and the quantity of stakes to be simultaneously performed warrants, manufacturers may deploy a multi-step semi-automated heat staking machine. In these systems, the automated controls govern more than just the heating and cooling processes, adding in such steps as automatic part positioning, alignment, error correction and even quality control and reporting. Multiple sensors and actuators can be utilized to automate as few or as many of these steps as a customer desires, and higher-level logic controllers and human interfaces can also be integrated into the systems to give operators increased data acquisition and performance feedback.

At the highest level, advanced heat staking can be performed in a fully automatic process. Incoming parts can be staged in large quantities at accumulation stations, fed continuously into a dedicated system that utilizes a multi-axis robot to orient and position each piece, and be consecutively staked until the batch is complete.

Fully automated heat staking comes at a premium cost, mostly due to the up- and down-stream robotics required. These automations are usually only found in the highest volume electronics or consumer goods manufacturing lines. Besides volume-related reasons, fully automatic heat staking is also selected for clean room applications where operators cannot be present. For most manufacturers, a semi-automatic solution is sufficient for their needs.

AMS Heat Staking Automations

Here at Automated Machine Systems, we offer multiple system platforms for heat staking, ultrasonic welding and other plastic joining processes. A few examples of our approach to automating the process include:

- AMS PJ-301 Plastic Joining system. This is a versatile, semi-standard platform for heat staking, ultrasonic staking, forming and other joining tool sets. This general-purpose platform begins with a standardized frame, enclosure, safety features, controls and operator interface. From there, we customize every system with part trays, joining tools, sensors and software functionality specific to each customer’s needs. This approach allows us to utilize a cost-effective, pre-engineered feature base to quickly adapt to lower-volume, moderately complex applications.

- AMS PJ-401 Plastic Joining system picks up where the PJ-301 system leaves off, adding advanced functionality for customers with higher volume, higher complexity and very custom applications. The PJ-401 uses multiple additional sensors, actuators and control capacity to provide very precise welding temperatures and pressures, exact and verified component positioning, integrated error-proofing and maximum repeatability. In addition, the PJ-401 can join parts of complex geometries, and with the advanced heat staking processes (and more) mentioned above.

To learn more about how automation could work for you, contact us for a free application review.