Get Informed With the MedFlex Cell Data Sheet

It’s free. Download now.

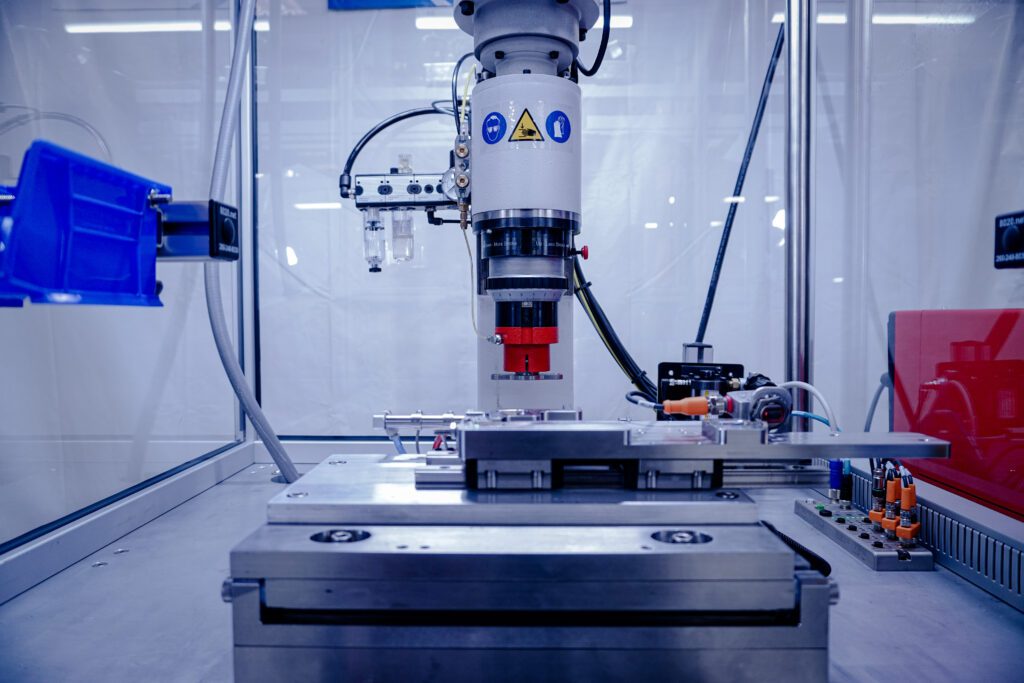

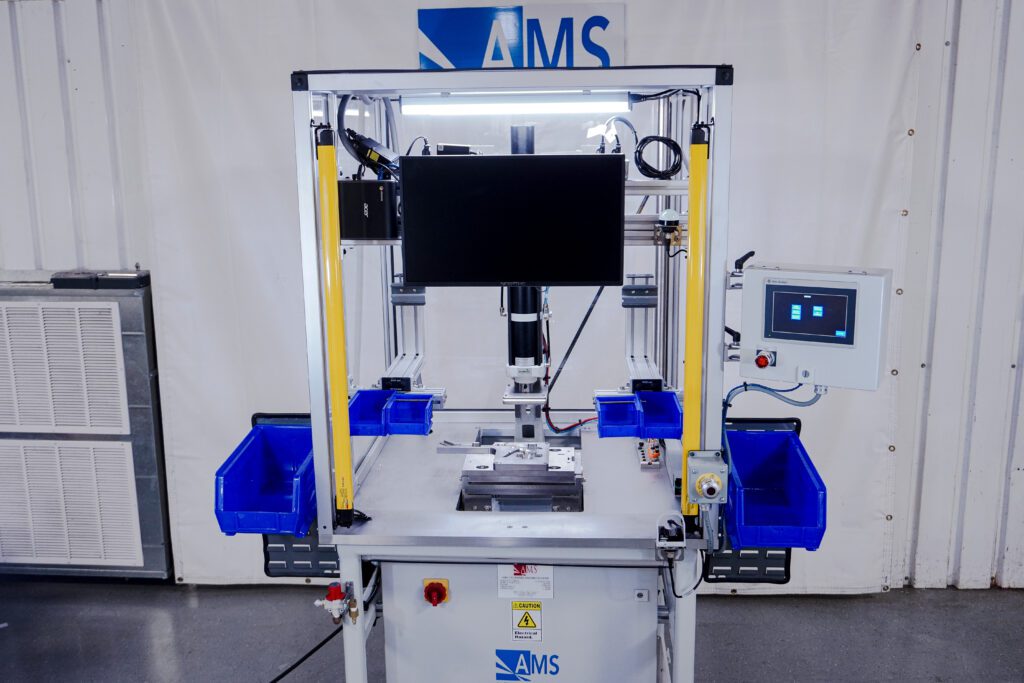

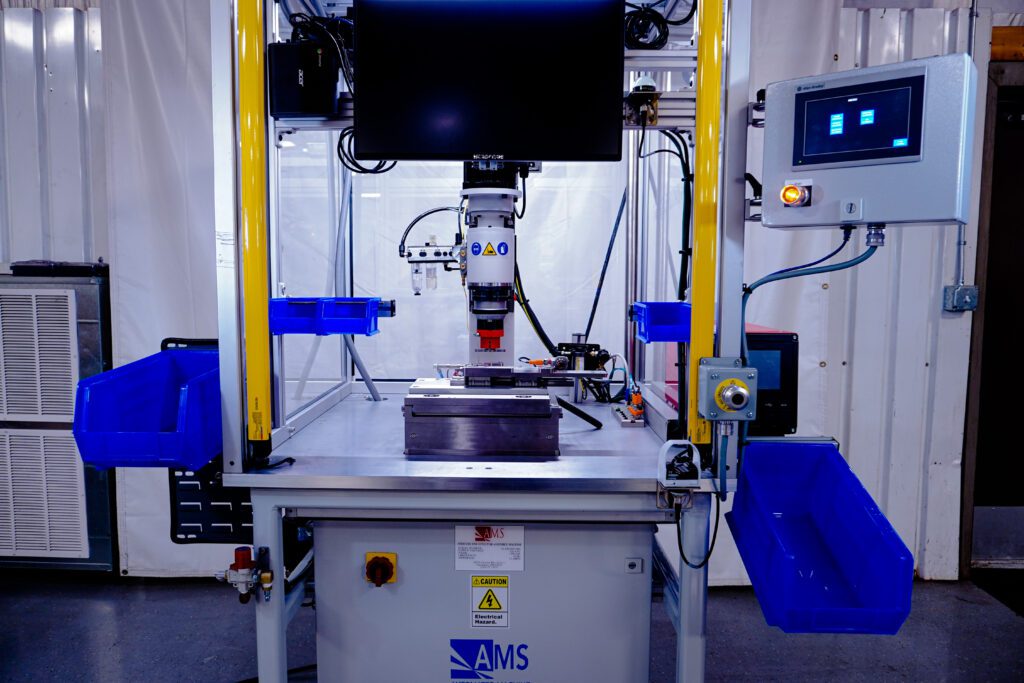

This medical kit assembly provides a semi-standard platform for precision medical assembly, installation and testing. The MedFlex Cell was designed to be configurable for a variety of healthcare device assemblies. From assembling catheter manufacturing equipment to leak testing medical hoses, this versatile cell will increase your manufacturing and assembly productivity by automating several steps.

What Are the Benefits of Automation in the Healthcare Industry?

Still not sure if automation is the right cure for your manufacturing headaches? Watch or read our case study about a Cincinnati-based medical device manufacturer that used automation to fast track their medical device assembly.

Medical Industry Automation Articles

Early Supplier Involvement Is Essential During Medical Device Development

Medical device manufacturers benefit by involving their suppliers early on in the development process. Medical device designers are under increasing pressure to develop medical devices faster and cheaper than their competitors. Project managers are seeking ways to cut timelines, streamline processes and tighten deadlines. The development of new medical devices takes several years, so when…

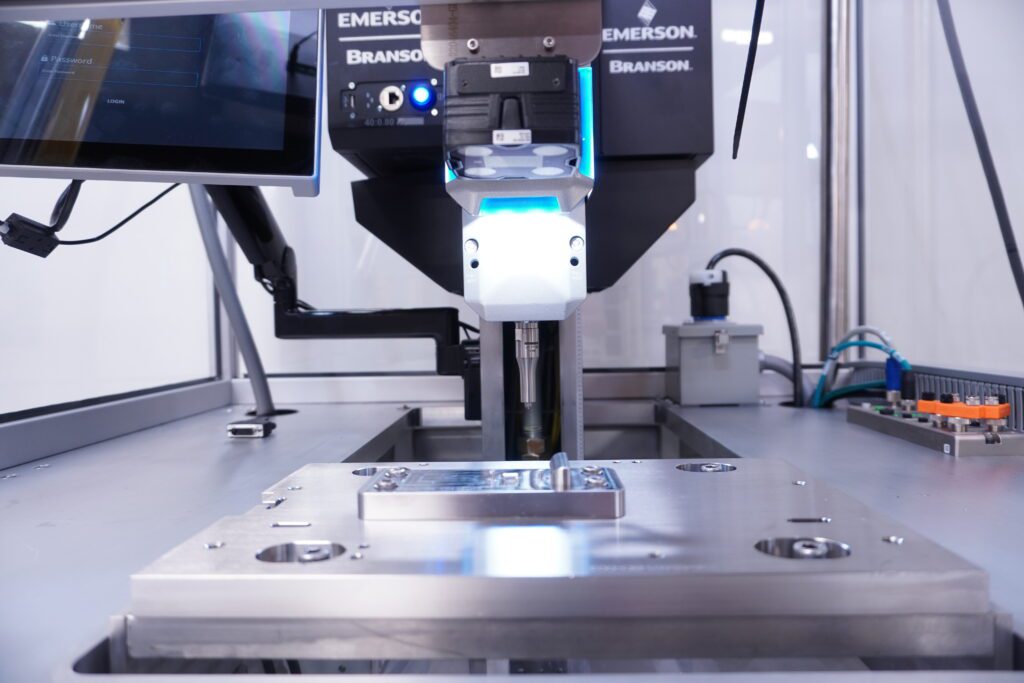

Heated Nut Insertion Automation Streamlines the Manufacturing Process

Whether it’s for an intake manifold, surgical light or lawn mower deck, attaching perfectly molded plastic parts to the rest of a sub-assembly can be a struggle. Fortunately, you can overcome that obstacle with precision heated nut insertion. Manufacturers across the automotive, medical device manufacturing and consumer product industries benefit from automating the nut insertion…

The Importance of Using Poka-Yoke Efficiently in Today’s World

There are billions of dollars invested in the manufacturing businesses all over the world. That’s why quality assurance is something that everyone talks about in every business. In order to keep production standards consistent, a lot of attention is given to what happens on at the production floors. There are various processes that are practiced…