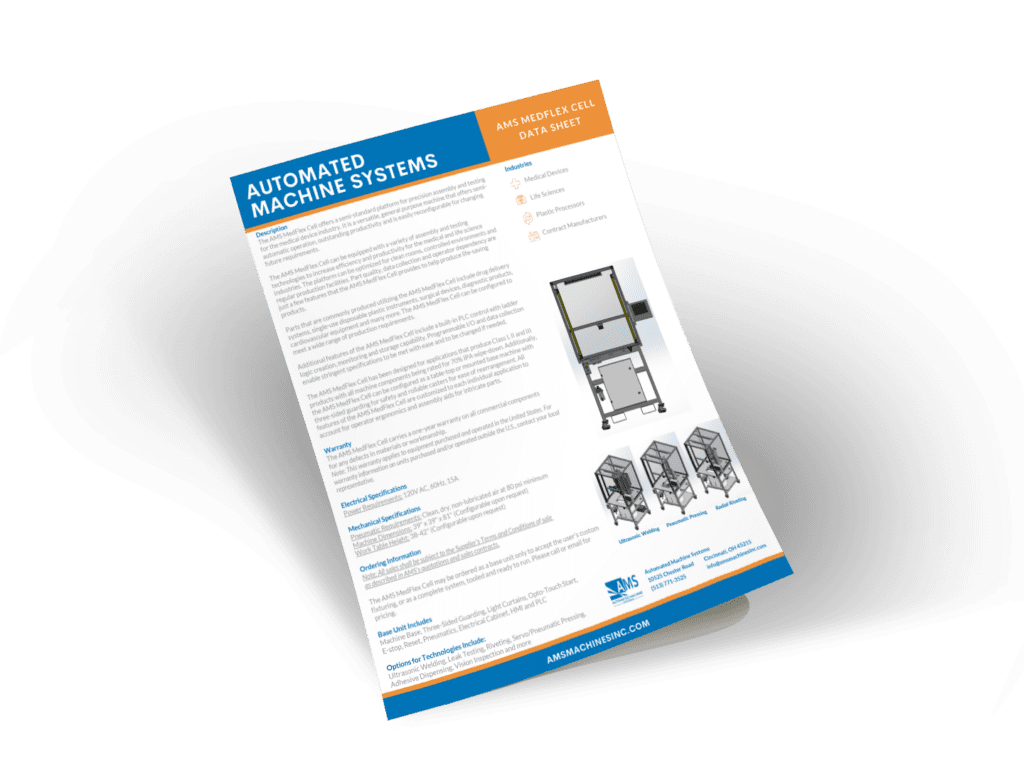

Get Informed With the MedFlex Cell Data Sheet

It’s free. Download now.

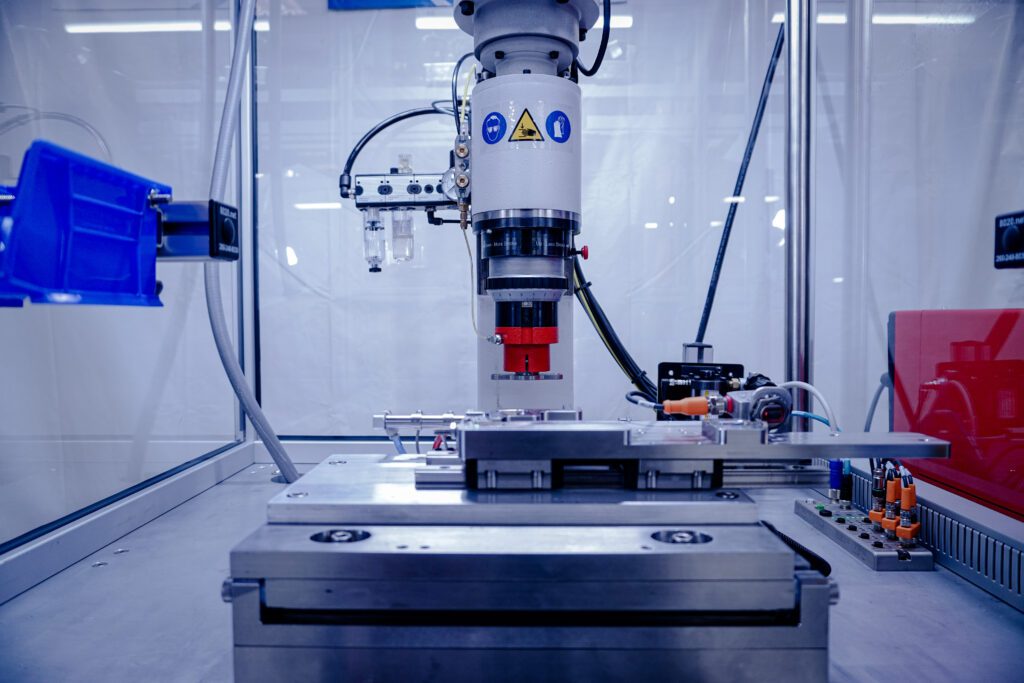

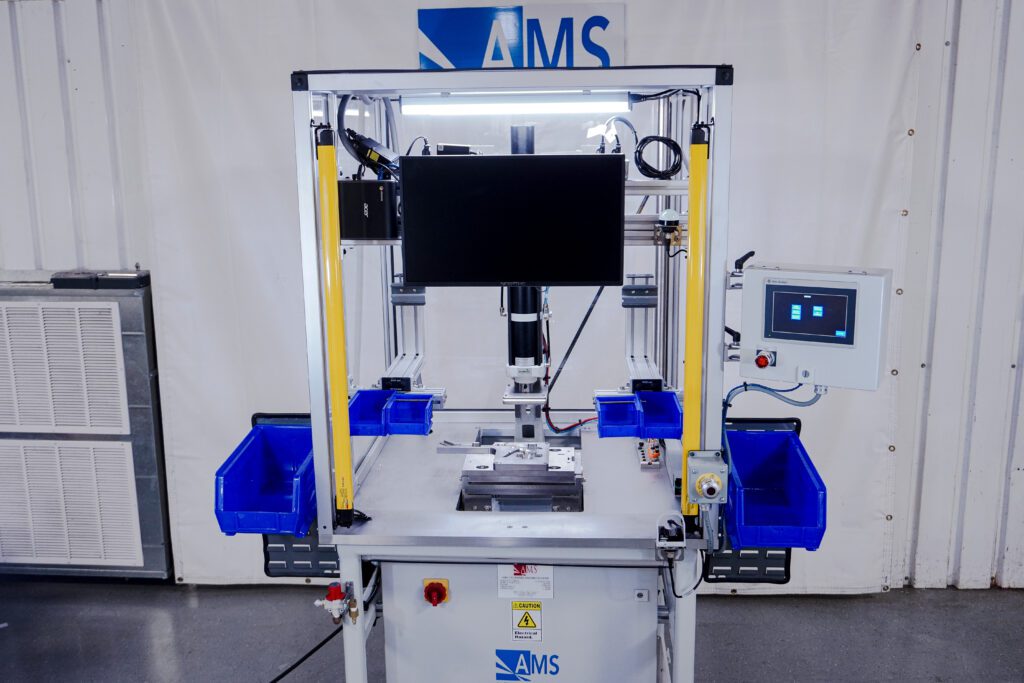

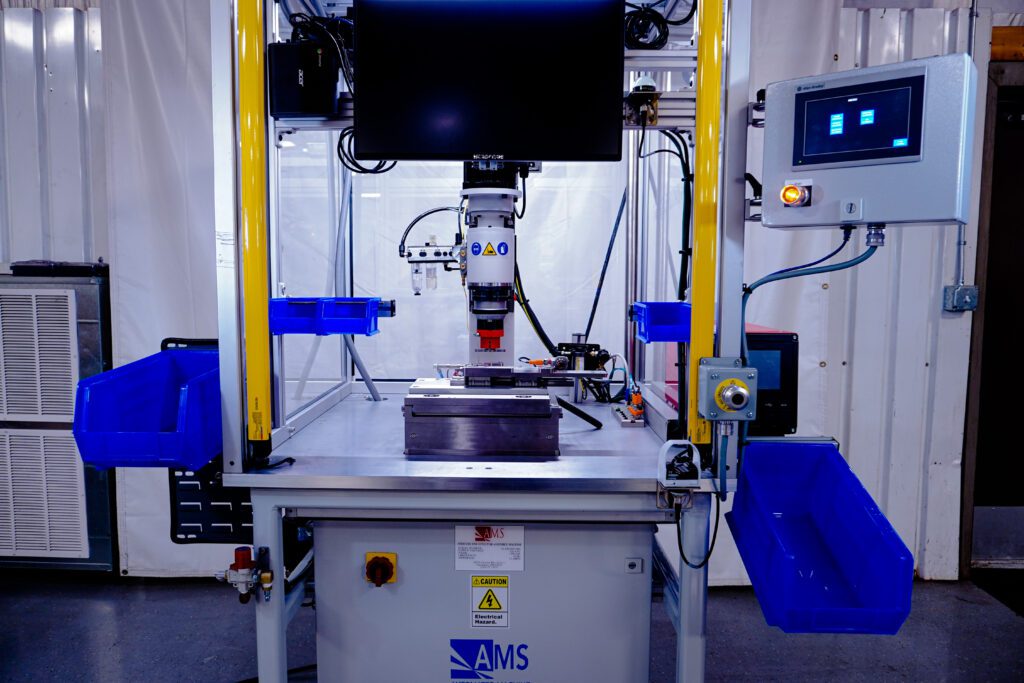

This medical kit assembly provides a semi-standard platform for precision medical assembly, installation and testing. The MedFlex Cell was designed to be configurable for a variety of healthcare device assemblies. From assembling catheter manufacturing equipment to leak testing medical hoses, this versatile cell will increase your manufacturing and assembly productivity by automating several steps.

What Are the Benefits of Automation in the Healthcare Industry?

Still not sure if automation is the right cure for your manufacturing headaches? Watch or read our case study about a Cincinnati-based medical device manufacturer that used automation to fast track their medical device assembly.

Medical Industry Automation Articles

IQ, OQ, PQ: What Do They Mean in Medical Device Manufacturing?

In the medical device manufacturing industry you have most likely come across the terms IQ, OQ and PQ, or at least heard them mentioned in passing. But what do these terms actually mean and why are they so vital to manufacturing in the medical industry? Installation qualification (IQ), operational qualification (OQ) and performance qualification (PQ)…

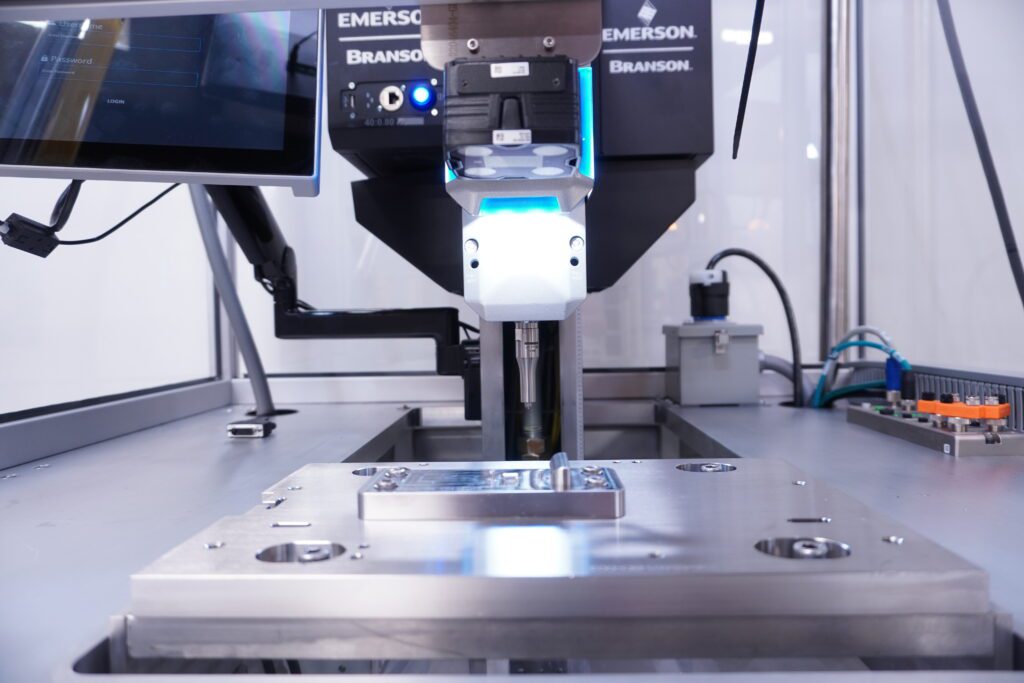

How to Enhance Your Medical Device Manufacturing Process by Upgrading Your Ultrasonic Welding Systems

In the realm of medical device manufacturing, any device being produced will require some amount of assembly. With technology today, this assembly is made more efficient and effective with the use of ultrasonic welding systems. With annual production volumes steadily increasing into the hundreds of millions, your ultrasonic welding system has likely been used for…

New AMS Facility Empowers Medical Manufacturing Automation

A recently completed expansion of the AMS facilities in Cincinnati, Ohio, allows our team to expand our capabilities and service offerings for automated machines to local medical manufacturers. The 8,000-square-foot expansion will help support our growth and the increased need for medical manufacturing automation in Ohio. “The launch of AMS Medical allows us to build…

Why More and More Medical Device Companies Turn to Manufacturing Automation Companies

Automation has been a popular resource in the manufacturing industry for a long time now. There are so many areas of manufacturing where automation can prove extremely helpful, which is why so many companies have adopted it into their process. That being said, the shift of medical device manufacturers toward manufacturing automation companies has been…

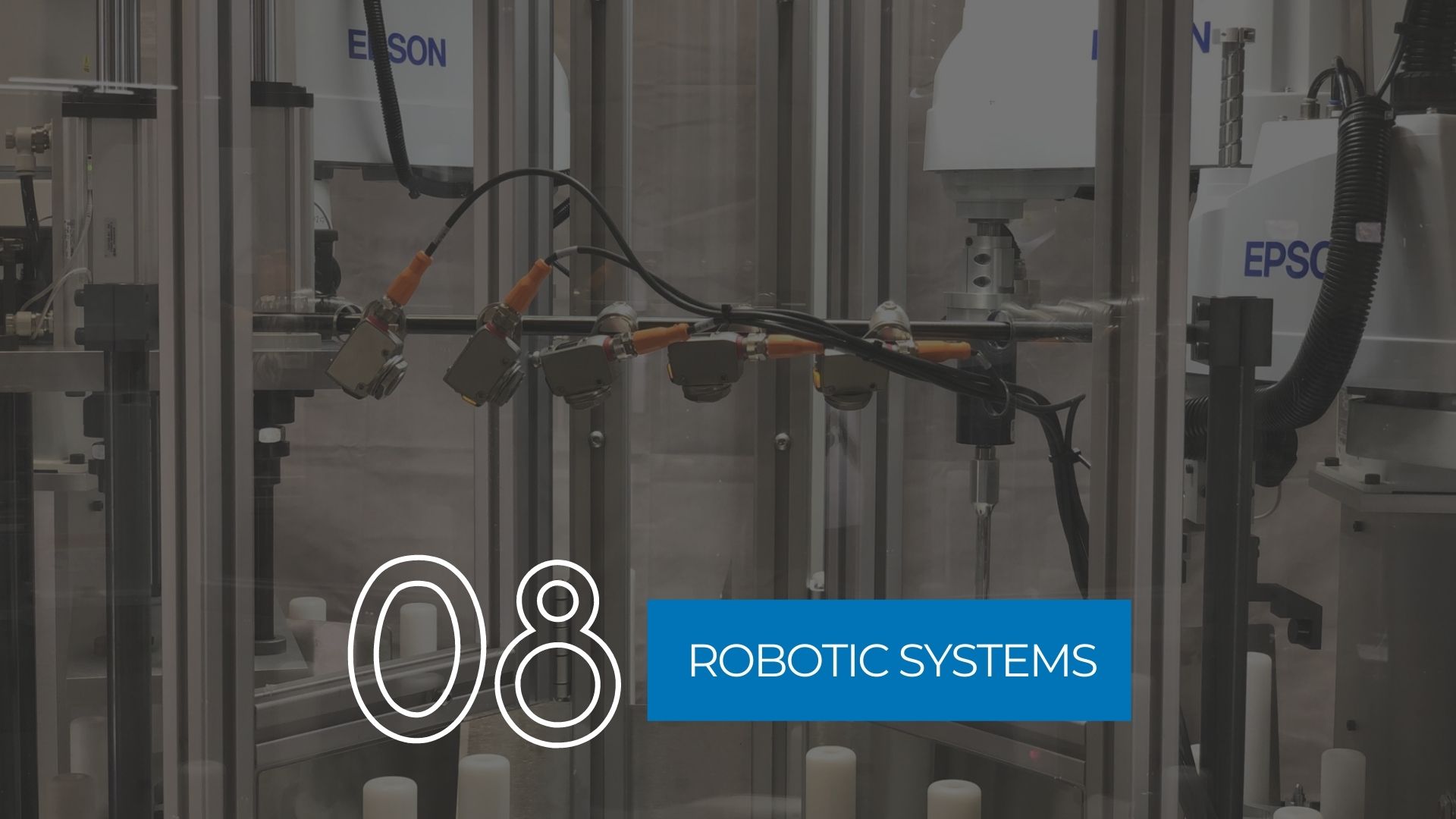

The Role of Robotic Process Automation in the Healthcare Industry

Robotic process automation (RPA) has been on the rise across all industries for a while, partially thanks to the COVID-19 pandemic, but also because of the wide range of benefits that automation provides businesses. Now that we are out of the pandemic, RPA is more popular than ever, especially in the healthcare industry. The benefits…

Challenges for Plastic Welding: Using Medical Devices Automation Equipment

The use of ultrasonic welders in manufacturing for plastics assembly has been a very effective approach. This includes manufacturing of all types of products including medical devices. That being said, plastic medical equipment welding comes with much stricter requirements than other plastics manufacturing. There are many things that must be considered when using medical devices…