Decades of experience in a range of industries

Proven processes for smooth delivery

Engineering and design expertise

Driving the Manufacturing Industry Forward With Automotive Automation

If we were forced to identify parts on a modern vehicle that weren’t made with the help of automotive automation manufacturing, we’d be hard-pressed to name a single one. Today, virtually every component that goes into assembling an automobile or truck is mass-produced on automated manufacturing lines by the hundreds or thousands.

There are two key reasons for automated manufacturing: One being the need for consistent high-quality products, and the other being the need to keep manufacturing costs at a minimum. By volume, most automotive components are low-tech, plastic or light metal commodities that are bought on price, which is the reason why manufacturing these parts is a highly price-sensitive endeavor.

Automotive automation is the perfect defense against cost variability, as well as the best solution for ensuring component safety, performance and a long lifespan. There are so many automated platforms that can be utilized in automotive component manufacturing that we’d like to run through the most common options below.

Industrial Automotive Component Manufacturing at a Glance

Manufacturing automotive components requires a wide array of fabrication tool processes. This fact is compounded further by the different materials and applications involved.

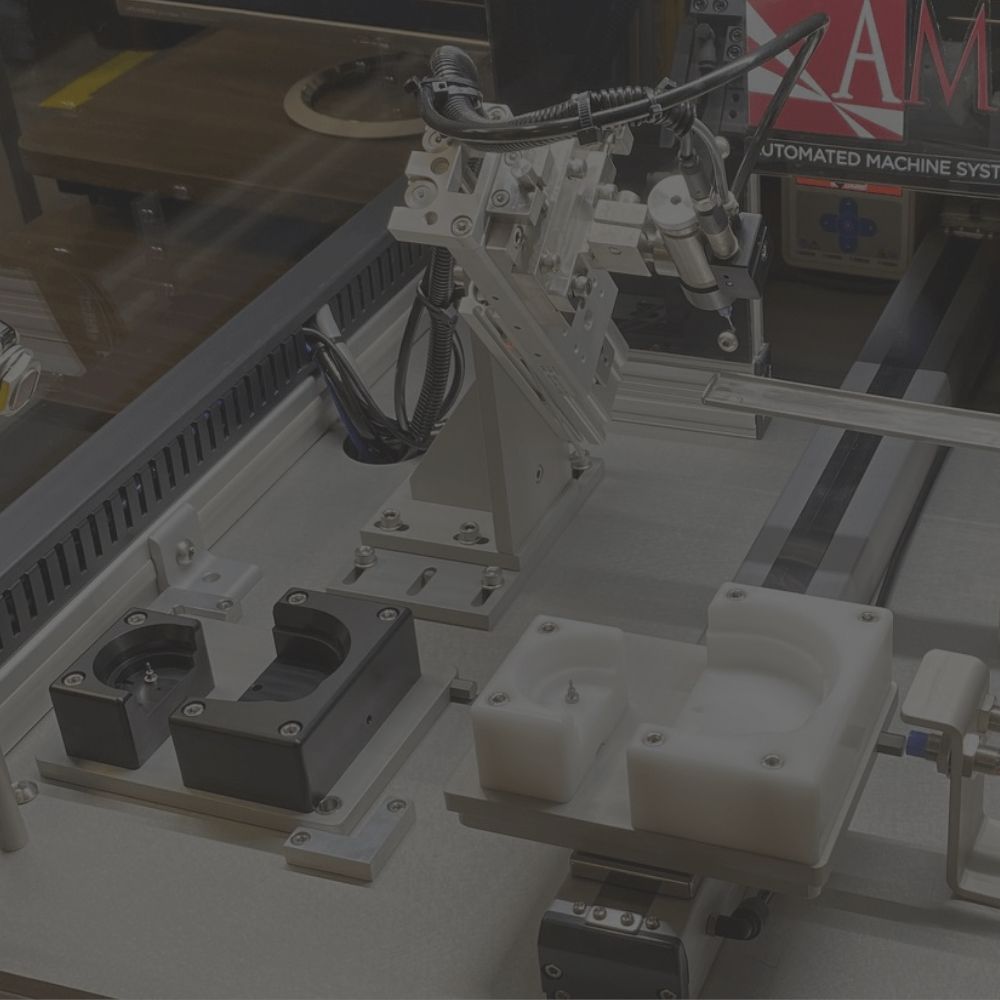

Applying Automation in the Automotive Industry

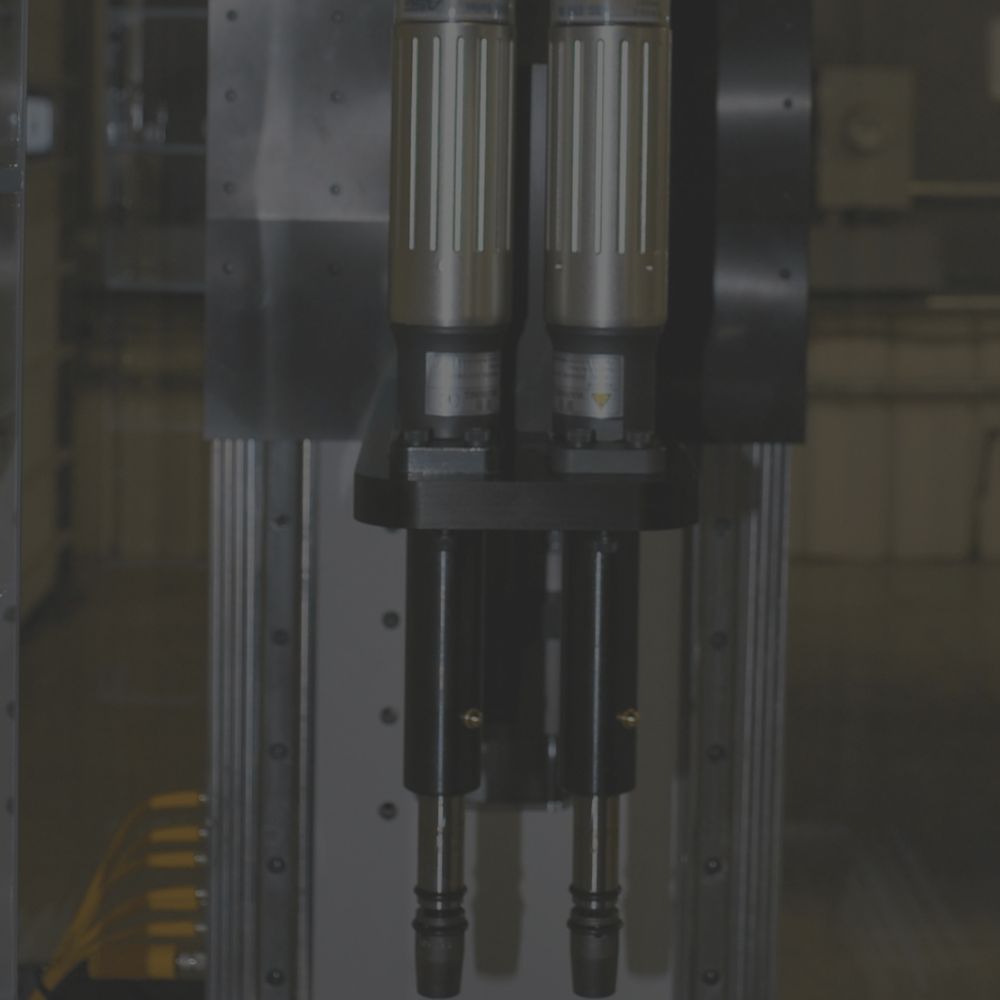

Nut Insertion

Our NI-401 Nut Insertion system is used to emboss threaded fasteners into plastic device molds, providing secure mounting points for medium- to high-load applications.

Precision Fastening

The PF-401 Precision Fastening system is used to automatically drive screws, studs, stand-offs and other threaded fasteners.

Leak Testing

Our LT-401 Leak Testing system performs all types of medical device quality control leak testing, including pressure decay, vacuum decay, mass spectrometry, and bubble test methods.

Adhesive Joining

AMS’ GC-401 Glue and Cure system is used to prepare, apply, fit and cure glued mating joints in plastic and metallic materials.

Plastic Joining

Our PJ-401 Plastic Joining system is used for single or multi-process fabrication needs, offering ultrasonic welding, fusion welding, heat staking, spin welding, spot welding and even textile welding.